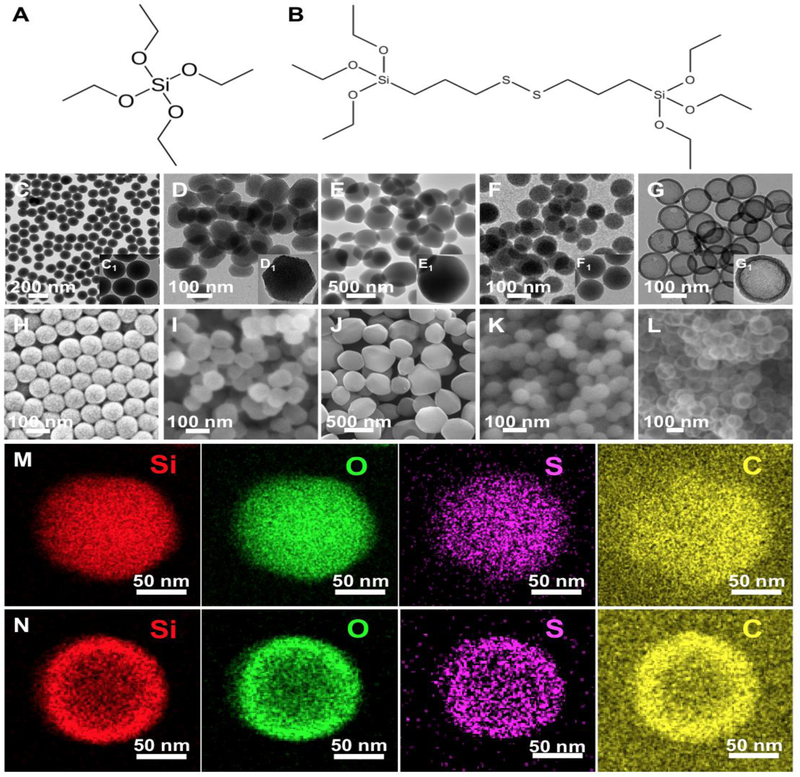

Figure 1.

Structure of the precursors used for fabrication of the nanoparticles; A: tetraethyl orthosilicate (TEOS) and B: bis[3-(triethoxysilyl)propyl] disulfide (BTESPD). C-G: TEM images of (C) Stöber 100, (D) Meso 100, (E) Meso 500, (F) Disulfide Meso 100, and (G) Disulfide Hollow 100 nanoparticles indicating the formation of particles with narrow size distribution. C1-G1 insets: TEM images of the particles under higher magnifications. H-L: SEM images displaying size, shape, and surface roughness of the nanoparticles. M and N: STEM images showing atomic density in Disulfide Meso 100 and Disulfide Hollow 100 particles. In these particles, sulfur (S) has a homogeneous distribution [16, 24].