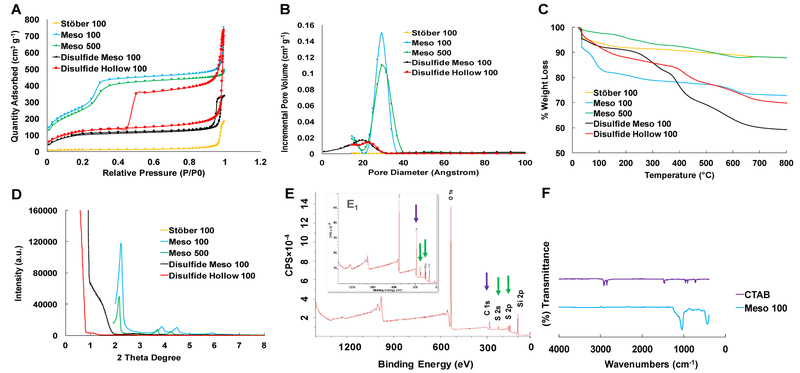

Figure 2.

Characterization of the fabricated nanoparticles. A: NPs nitrogen adsorption-desorption isotherms indicating type IV for mesoporous particles and type III for nonporous dense Stöber 100 particles. B: pore size distribution confirming the presence of 2-3 nm pores in mesoporous particles. C: TGA graphs showing more weight loss in disulfide-based particles due to the existence of …Si-O-Si-C-C-C-S-S-C-C-C-Si-O-Si… hydrophobic backbone structure. D: XRD plots of the particles confirming the presence of Bragg peaks in Meso 100 and Meso 500 nanoparticles and the absence of these peaks in Disulfide Meso 100 and Disulfide Hollow 100 particles. E: XPS spectra for Disulfide Meso 100 (inset) and Disulfide Hollow 100 particles revealing the incorporation of BTESPD precursor in these particles during the fabrication step. Purple and green arrows show the presence of carbon and sulfur atoms, respectively. F: FT-IR analyses for CTAB and Meso 100 particles which confirms the absence of typical CTAB peaks around 3000 cm−1 in washed Meso 100 nanoparticle.