Table 2.

Optimization of the reaction conditions for the synthesis of enantioenriched chloro‐substituted allenylsilane (S)‐3 c.[a,b]

|

Entry |

Cat. (mol %) |

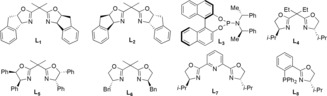

Ligand* (mol %) |

Base (2.0 equiv) |

Solvent |

T [°C] |

Yield [%] |

ee [c] [%] |

|---|---|---|---|---|---|---|---|

|

1 |

CuI (10) |

L1 (12) |

Et3N |

MeOH |

−10 |

29 |

47 |

|

2 |

CuI (10) |

L2 (12) |

Et3N |

MeOH |

−10 |

7 |

50 |

|

3 |

CuI (10) |

L3 (12) |

Et3N |

MeOH |

−10 |

91 |

0 |

|

4 |

CuI (10) |

L4 (12) |

Et3N |

MeOH |

−10 |

17 |

10 |

|

5 |

CuI (10) |

L6 (12) |

Et3N |

MeOH |

−10 |

32 |

10 |

|

6 |

CuI (10) |

L7 (12) |

Et3N |

MeOH |

−10 |

68 |

8 |

|

7 |

CuI (10) |

L8 (12) |

Et3N |

MeOH |

−10 |

27 |

2 |

|

8 |

CuI (10) |

L2 (12) |

Et3N |

EtOH |

−10 |

12 |

40 |

|

9 |

CuI (10) |

L2 (12) |

PPD |

MeOH |

−10 |

22 |

52 |

|

10 |

CuI (10) |

L5 (12) |

PPD |

MeOH |

−10 |

61 |

60 |

|

11 |

CuI (10) |

L5 (12) |

TMP |

MeOH |

−10 |

61 |

66 |

|

12 |

CuI (10) |

L5 (12) |

TMP |

MeOH |

−30 |

53 |

74 |

|

13 |

CuF2 (10) |

L5 (12) |

TMP |

MeOH |

−30 |

60 |

86 |

|

14 |

CuF2 (10) |

L5 (20) |

TMP |

MeOH |

−30 |

62 |

90 |

|

15 |

CuF2 (5) |

L5 (10) |

TMP |

MeOH |

−30 |

62 |

84 |

|

| |||||||

[a] Reaction was run under the following reaction conditions: 1 c (0.2 mmol), 2 (0.4 mmol, 2.0 equiv), base (0.4 mmol, 2.0 equiv), 10 mol % copper catalyst, and ligand in 1.0 mL of either anhydrous MeOH or EtOH at indicated temperature under argon atmosphere for corresponding time. [b] Yield of isolated product. [c] The ee values were determined by HPLC analysis. PPD=piperidine, TMP=2,2,6,6‐tetramethylpiperidiene.