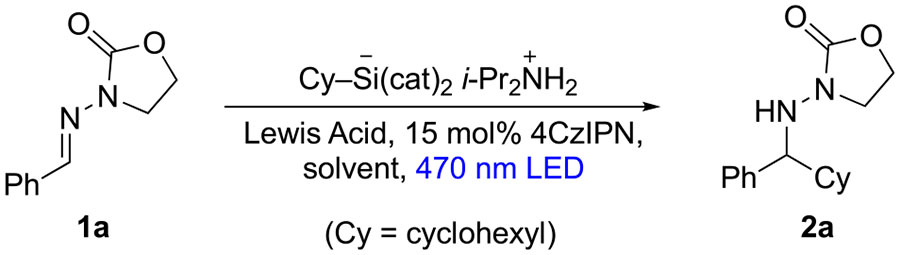

Table 1.

Optimization of Radical Addition Reaction

| |||||

|---|---|---|---|---|---|

| entry | Lewis acid (2 equiv) | silicate (equiv) | solvent | time (h) | % conva |

| 1 | none | 2 | DMSO | 24 | 40 |

| 2 | none | 2 | DMSO | 49 | 48 |

| 3 | ZnBr2 | 1 | DMSO | 18 | 27 |

| 4 | Zn(OTf)2 | 1 | DMSO | 18 | 27 |

| 5 | ZnBr2 | 2 | DMSO | 18 | 63 |

| 6 | ZnBr2 | 4 | DMSO | 18 | 64 |

| 7 | ZnBr2 (3 equiv) | 2 | DMSO | 18 | 49 |

| 8 | MgCl2 | 2 | DMSO | 18 | 59 |

| 9 | MgBr2 | 2 | DMSO | 18 | 54 |

| 10 | Mg(OTf)2 | 2 | DMSO | 18 | 31 |

| 11 | ZnBr2 | 2 | DMF | 16 | 28 |

| 12 | MgCl2 | 2 | DMF | 16 | 44 |

| 13 | MgCl2 | 1.2 | EtOH | 23 | 10 |

| 14 | MgCl2 | 2.6 | DMSO | 48 | 86 |

| 15 | MgCl2 | 3 | DMSO | 48 | 22b |

| 16 | MgCl2 | 3 | DMSO | 48 | 68c |

| 17d | MgCl2 | 3 | DMSO | 47 | 88 (60e) |

| 18 | MgCl2 | 2 | DMSO | 24 | 73 |

Determined by 1H NMR integration.

1 mol % of catalyst loading.

5 mol % of catalyst loading.

Conversions in control experiments using conditions of entry 17: Absence of blue LED (0%), absence of 4CzIPN (0%), open to air (67%), replacing silicate with CyBF3K (59%).

Isolated yield.