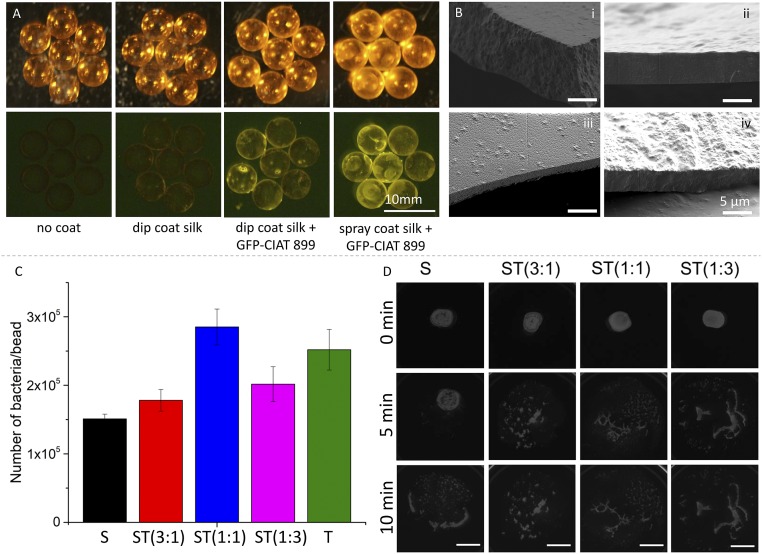

Fig. 2.

Coating manufacturing, inoculant encapsulation, and material degradation. (A) Single-pot coating of glass beads used as seed phantoms with dip-coating and spray drying techniques. Green fluorescent protein (GFP)-modified CIAT 899 allowed to visualize bacteria distribution on the glass beads. (B) Scanning electron microscopy (SEM) micrographs depicting the cross section of (i) silk (S), (ii) ST 3:1 ST(3:1), (iii) ST(1:1), and (iv) ST(1:3) coatings obtained by dip coating. The resulting film thickness was circa 5 μm. The 4 micrographs have been taken at the same magnification. (C) Investigation of bacteria encapsulation efficacy during the dip-coating process. The quantity of bacteria per bead after dip coating was quantified by colony counting. All coating solutions had similar dry matter concentration, number of bacteria, and viscosity. Error bars indicate SD. (D) Degradation of coating films encapsulating GFP-CIAT 899. Films were positioned on thin phytagels, which were used as transparent artificial soil. Film degradation was investigated as a function of time. Top views of films transilluminated with fluorescence light were taken using a ChemiDoc MP imaging system. (Scale bar is 1 cm.)