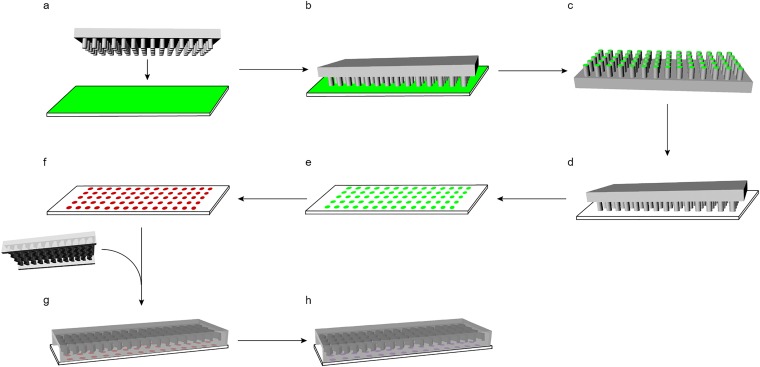

FIG. 1.

Platform preparation using microstamping. (a) A PDMS microstamp is fabricated by photolithography with 30 μm diameter columns spaced 150 μm center-to-center and a clean glass slide is spin-coated with gelatin for hydrodynamic patterning or Zetag for self-assembled patterning. (b) The microstamp and the glass slide are placed in conjunction. (c) The ink is transferred onto the microstamp. (d) A plasma-treated glass slide and the inked stamp are placed in conjunction. (e) The ink is transferred to the plasma-treated glass slide yielding a microarray. (f) Particles particular to the form of patterning (streptavidin-polystyrene nanoparticles for hydrodynamic patterning or E. coli bioparticles for self-assembled patterning) are deposited onto the substrate. (g) The microchannel with a length of 40 mm, width of 2.5 mm, and a total height of 90 μm (with a 50-μm distance from the glass surface to the herringbone design) was irreversibly bound to the particle-patterned slide via oxygen-plasma treatment. (h) For hydrodynamic patterning, biotinylated antibodies are added with flow through the microchannel.