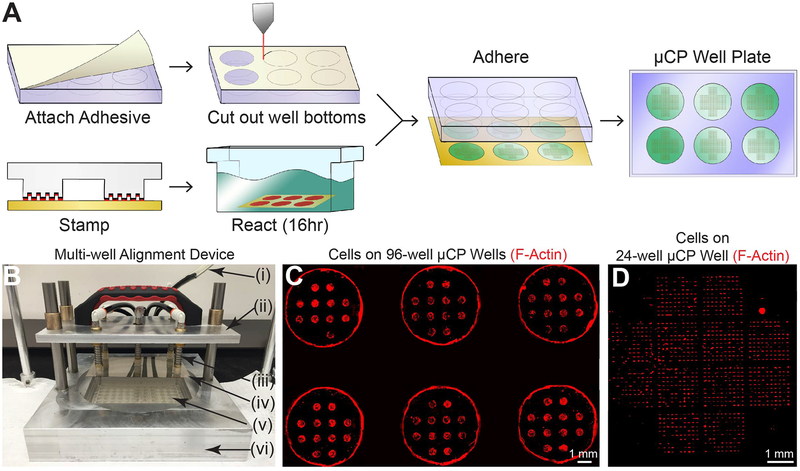

Figure 1. μCP Well Plates.

A) Workflow for creation of μCP Well Plates. B) Multi-well alignment device for μCP Well Plate assembly. Pictured: vacuum line (i), lift arm for vacuum tooling (ii), spring-leveled vacuum cup tooling (iii), micropatterned glass sheet (iv), 96-well plate with attached adhesive and cut-out well bottoms (v), and aluminum base with machined cavities designed to fit various μCP Well Plate components (vi). C) Cells on a 96-well μCP Well Plate. 6 wells of a fully patterned 96-well plate containing twelve circular features (300 μm radius) per well are shown. Human fibroblasts were seeded 72 hours prior to TRITC-phalloidin staining and imaging. Fluorescent signal at edge of wells is due to auto-fluorescence of tissue culture plastic at well edges, not cells at these locations. Inter-well areas are masked for clarity. D) Cells on 24-well μCP Well Plate. One well of a 24-well plate containing twelve 10×10 single-cell feature arrays per well is shown. Human fibroblasts were seeded 16 hours prior to TRITC-phalloidin staining and imaging.