Abstract

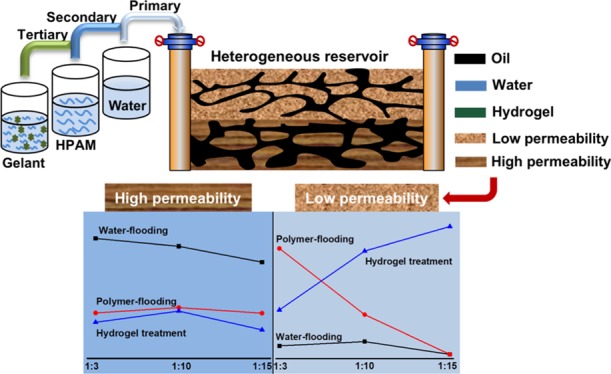

Premature water production is an inevitable issue that results in loss of quantities of reserves in heterogeneous oilfields especially with large permeability ratios. Hydrogel treatments, preferentially plugging large channels, are efficient techniques to reduce excessive water circulation. In this work, a moderate delayed polyacrylamide hydrogel was fabricated applying in-depth plugging to promote oil production. Suitability tests of delayed hydrogel in the presence of quartz sand confirmed its mature delay over 10 days, providing the low-viscosity gelant sufficient time for entering the deep layer. Single sand-pack displacement tests demonstrated the excellent plugging ability in differential permeability layers to strongly promote the follow-up oil production. Aiming at heterogeneous reservoirs with three different permeability ratios, conventional displacements and hydrogel treatments were sequentially conducted. In comparison with water- and polymer-flooding that mainly performed exploitation at low-permeability-contrast layers (Khigh/Klow = 3), the delayed hydrogel technique after polymer-flooding was capable of improving the oil recovery efficiency of unswept zones at high-permeability-contrast zones (Khigh/Klow ≥ 10). Recovery in heterogeneous layers with permeability ratios (Khigh/Klow) of 10 and 15 was enhanced to 48 and 59%, respectively from 18 and 0%. In addition, rheological behaviors and morphologies elucidated the delayed hydrogel with extruding deformation and high yield strength, facilitating water shutoff and improvement of oil production.

Introduction

Excessive water production earlier in heterogeneous reservoirs often led to unproductive cycling of injected enhanced oil recovery (EOR) chemicals, whereas large amounts of residual oil remained in subterranean region.1−5 Long-term chase flooding always enters large permeability layers, leaving otherwise low permeability zones unswept or poorly swept.6−8 Most oilfields were discovered in continental sedimentary basins, which were characterized by complicated oilfield geologies having high-permeability contrasts.9 To enlarge the sweeping area, plugging agents were required to be injected into the depth of the formation to block large channels so that the subsequent fluids get diverted to the previously unswept oil-rich layers.10,11 Gel treatment is one of the most cost-effective techniques for water shutoff and sweeping improvement.

Varieties of hydrogels have been studied for oil recovery.12−22 Many studies enhanced recovery through particle gel16,18,19,21 or microgel20 technology corresponding to the oilfield geometry. Surfactants combining with gels12,16 were utilized for improving the recovery efficiency. Even the porous medium was controlled by promoting the sealant strength to reduce heterogeneity13,14,17 or by treating special geological configurations.15 Among these technologies, polyacrylamide gels were extensively used for managing the water yield.23−31 Nano particles such as clay,23 montmorillonite,24 and cellulose32 were chosen to improve the strength of hydrogels for EOR. Particle gels,33,34 directly or through re-cross-linking, were injected into the large channels acting as plugging agents. Active microorganisms were immobilized into the polymer gels, which help to improve oil recovery through metabolizing carbonate and bioactive components of surfactants or ammonium.31,32 However, most of these hydrogels were hardly applied in displacement practice or in oil recovery. Although a few of them were evaluated in simple core-flooding operations,25,27−34 conventional gels always formed plugging in the immediate vicinity of the wellbore, leading to chase water detouring to the far untreated high permeability zones.35−37 Therefore, delayed hydrogel treatment was further prompted for deep plugging. Delayed cross-linking can be adjusted through cross-linkers, ligands that form complexes with host cross-linkers, or slow-release synthesis. One possible way was reported38 using strong ligands such as malonate or glycolate to associate with Cr(III), and a delay occurred till the binding construction of the ligand with the crosslinker. Cordova et al.39 used polyethylenimine (PEI) and dextran sulfate (DS) to entrap and control the release of Cr(III) in polymer–Cr(III) fabrication, however, the delay strongly relied on the pH, ionic strength, and temperature. As a primary release-controlled agent, DS was too expensive to be widely used in oilfields. Jayakumar and Lane40 chose 2-acrylamido-2-methylpropane sulfonic acid41 as a high-temperature delayed source substituting DS to combine with PEI achieving several days delay at 100 °C. However, the gelation at low temperature is uncertain because PEI was mainly applied at medium and high temperatures.42−44 Xu45 designed a delayed gel based on the slow release of methenamine, phenol, and citric acid cross-linkers from the cavity of β-cyclodextrin, and the release highly depended on the hydrophobicity of the competitive long-chain fatty alcohol in hydrolyzed polyacrylamide (HPAM) solutions. Thus, a cost-effective and easily fabricated delayed hydrogel was extremely needed for deep plugging.

In this study, partially hydrolyzed PAM (HPAM) with a moderate hydrolysis degree of 5% was utilized to form coordination cross-linking with Cr(III) acetate through intermediate complexes46 to prolong gelation, and the resulting system exhibited over 10 days delay, which is beneficial to function in-depth plugging. The viscosity, yield stress, and morphology of the delayed hydrogel were studied to examine the deformation, migration, and extruding behaviors. Suitability and corresponding plugging performance in quartz sand were verified through static gelling and single-sand-pack displacement tests. Furthermore, double-core tests displayed how to increase the sweeping efficiency of the delayed hydrogel and HPAM in heterogeneous layers with low-, medium-, and high-permeability ratios (≥10). The distinctions and advantages of the delayed hydrogel treatment at differential heterogeneity were presented.

Results and Discussion

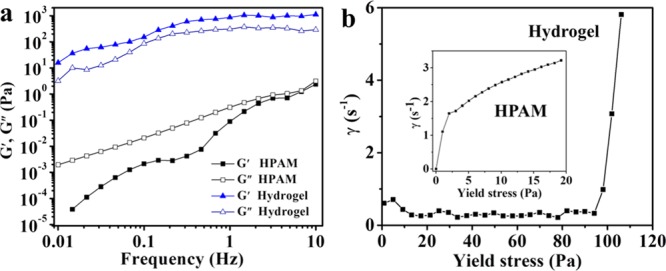

Rheological Behaviors of Polymer Hydrogels

The rheological behaviors of HPAM and hydrogels were analyzed to inspect the viscoelastic extrusion during oil extraction. For HPAM, both elastic (G′) and viscous moduli (G″) increased with an increasing shear frequency, as shown in Figure 1a. G″ increased from 10–3 to 3.1 Pa as the shear frequency increased to 10 Hz. G″ was always larger than G′, revealing a viscous shear-thickening fluid. Exhibiting a low yield stress of 1.1 Pa (Figure 1b), HPAM was easily induced to flow once the external stress was above 1.1 Pa, which would effectively decrease the mobility ratio between oil and water for polymer-flooding because of its high mobility. As a result, polymer-flooding enlarged the sweeping area of the targeted reservoir after suffering from unproductive cycling of water displacements. As for hydrogels, G′ and G″ were 103 to 105 times larger than those of HPAM, and G′ was always larger than G″, indicating an elastic fluid of hydrogels, which showed distinct differences from HPAM (Figure 1a). As shear frequency increased, G′ increased to 1100 Pa, demonstrating the extraordinary elasticity of the hydrogel. While suffering from shear, hydrogels sustained a high elastic deformation. Besides displaying a high yield stress of 101.9 Pa, the hydrogel cannot be driven until the stress was increased above 101.9 Pa (Figure 1b). Once the hydrogel is formed in the porous channel, it is too difficult to be extruded out. The behaviors indicated that the hydrogel is a reliable plugging agent for reducing excessive water production.

Figure 1.

(a) Elastic (G′) and viscous (G″) moduli of both HPAM and hydrogels as a function of frequency and (b) comparison of the yield stress for HPAM and hydrogels.

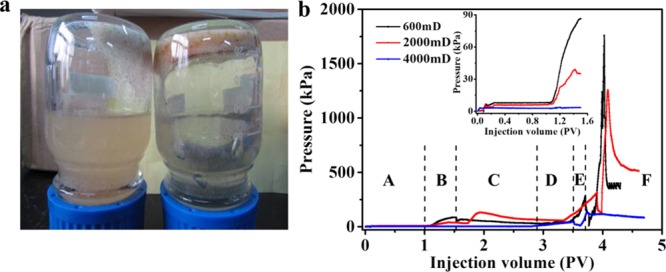

Suitability of a PAM Hydrogel to a Heterogeneous Permeability Layer

To evaluate suitability of the as-prepared gelant with quartz sand, static gelation blending with 100 mesh quartz sand in a ratio of 3:1 was conducted at 45 °C. Figure 2a compares the states of quartz sand before and after gelling. Before that, all the quartz sand that dispersed in the low-viscous gelant dropped off because of gravity once the beaker was inverted (on the left in Figure 2a). After 10 days of gelling under 45 °C, the gelant gelatinized. No quartz sand dropped but was suspended stably at the bottom (on the right in Figure 2a). Unlike the complete dispersion initially, the sand was binding together with the viscous hydrogel. Also, the gelation time almost kept constant even though blending with sand, suggesting little static adsorption quartz sand with the gelant. Additionally, mixing with quartz sand, the hydrogel maintained thermal stability at 45 °C for several months and even longer. The results illustrated the excellent suitability of the hydrogel with quartz sand that constituted the sand-pack models.

Figure 2.

(a) Comparison of quartz sand before and after gelling (left: no gelling; right: gelling), (b) pressure curves of three different single sand-pack model tests during the entire displacement phrase (A: first water flooding, B: polymer flooding, C: second water flooding, D: delayed hydrogel treatment, E: third water flooding; and F: fourth water flooding).

Figure 2b compares the displacement pressures of three different permeability sand-pack models. After the first water-flooding for permeability measurement, 0.5 PV slug of 1000 mg/L polymer acting as a profile control agent was injected. The injection pressures during polymer-flooding increased and varied distinctly among the three sand packs. For a low permeability model of 0.6 μm2, the pressure increased to 275 kPa from 11.3 kPa. The pressure of the permeability model of 2 μm2 increased to 38 kPa. With regard to the high permeability of 4 μm2, the pressure was merely 3.5 kPa during the polymer injection of 0.5 PV slug. This comparison indicated that the polymer performed an excellent profile modification in the low permeability model. After the second water-flooding, a slug gelant of 0.7 PV was injected, respectively. The third water-flooding was run to drive the gelant to the depth of the models. Following that, the models were under 45 °C for gelling. Until complete gelation, the fourth water-flooding was conducted to investigate the plugging effect in different permeability models. Figure 2b shows that three curves increased sharply to maximum pressures, suggesting the block of large channels. Through hydrogel treatment, as shown in Table 1, the residual resistance factor (RRF) of low, medium, and high permeability models were 400, 80, and 32, respectively; this is why the peak pressure of three different permeability models during water-flooding achieved 1759, 1257, and 130 kPa. Obviously, the larger the RRF, the higher the maximum displacement pressure. The chase water was repelled to enter small unswept channels after high permeability zones were plugged. Correspondingly, the permeability of the plugged models decreased to 1.5, 25, and 125 μm2 from the initial 600, 2000, and 4000, indicating favorable plugging. The single sand-pack displacement results strongly supported that the gelant can well-adapt to achieve efficient plugging in differential permeability models.

Table 1. Results of Plugging Tests in Single Sand-Pack Modelsa.

| parameter | test 1 | test 2 | test 3 |

|---|---|---|---|

| permeability k1 (×103 μm2) before injecting | 600 | 2000 | 4000 |

| permeability k2 (×103 μm2) after injecting | 1.5 | 25 | 125 |

| RRF | 400 | 80 | 32 |

Note: RRF, residual resistance factor, RFF = k1/k2.

Morphology of HPAM and Hydrogels

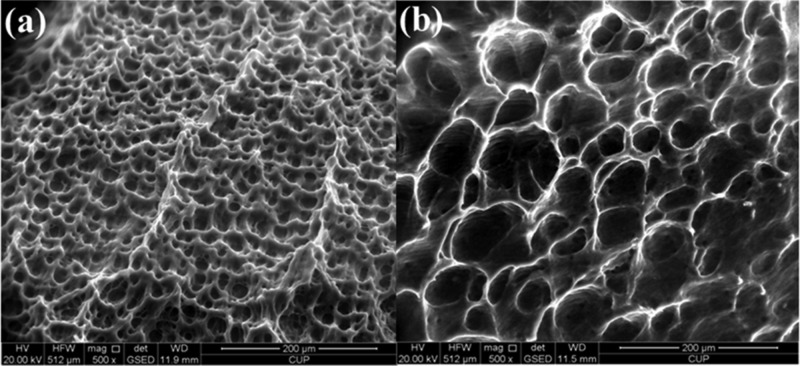

PAM polymer acting as profile modification agent could increase the mobility ratio between chase water and crude oil, thus to enlarge the sweeping area, but it seldom exerts positive control in high permeability zone. Fortunately, the robust delayed hydrogel could block large paths to improve sweeping efficiency. These two distinct effects may be closely related to their morphology. As shown in Figure 3, HPAM revealed a regular sparse framework which overlapped layer by layer. It seems that the framework was interwoven by means of the entangled polymer that was mainly responsible for the network. A large amount of transparent pores appeared with sizes ranging between 10 and 20 μm. The pores were nearly filled with flowing water together with a loose framework and may determine the polymer having high mobility for migration during polymer displacement. Also, the polymer would be propelled easily by the chase fluid. By contrast, the morphology of hydrogels exhibited solid frameworks, and no apparent pores appeared. The structure beneath the surface was invisible owing to the dense network. It appeared that the pores (Figure 3b in black) were filled with aggregated bundles, which formed a robust structure, resulting in higher strength than the polymer. The hydrogel could still hold the function of plugging in the reservoir, though the chase water-flooding was continuously carried out.

Figure 3.

Morphology of both (a) HPAM and (b) hydrogels.

Enhanced Oil Recovery in Double-Core Displacement Tests

To investigate oil recovery efficiency of delayed hydrogel treatment after polymer-flooding in heterogeneous reservoirs, double-core experiments with three different permeability contrasts of 1:3, 1:10, and 1:15 were conducted to study the flooding pressure, fractional flows, and enhanced oil recovery during displacement. The parameters of core samples and oil recoveries at different stages are summarized in Table 2.

Table 2. Key Parameters of Heterogeneous Double-Core Models during Displacementa.

| permeability contrast coefficient for core | ||||||

|---|---|---|---|---|---|---|

| 1:3 |

1:10 |

1:15 |

||||

| parameter | high | low | high | low | high | low |

| permeability k (μm2) | 900 | 300 | 3000 | 300 | 4500 | 300 |

| porosity ϕ (%) | 28.89 | 26.62 | 31.09 | 27.1 | 30.68 | 26.16 |

| initial oil saturation So (%) | 77.5 | 75.45 | 75.8 | 75.0 | 70.82 | 70.6 |

| Rw (%) | 52.42 | 4 | 48.91 | 6.01 | 41.71 | 0 |

| Rpw (%) | 18.6 | 49.64 | 21.02 | 18.62 | 18.48 | 0 |

| RGw (%) | 14.34 | 20.82 | 19.44 | 48.42 | 10.9 | 59.9 |

| EOR (%) | 17.4 | 33.19 | 33.42 | |||

| total oil recovery (%) | 78.36 | 81.20 | 75.25 | |||

Note: Rw, oil recovery of water-flooding; Rpw, oil recovery of polymer-flooding; RGw, oil recovery after hydrogel treatment; EOR, enhanced oil recovery.

Permeability Ratio of 1:3

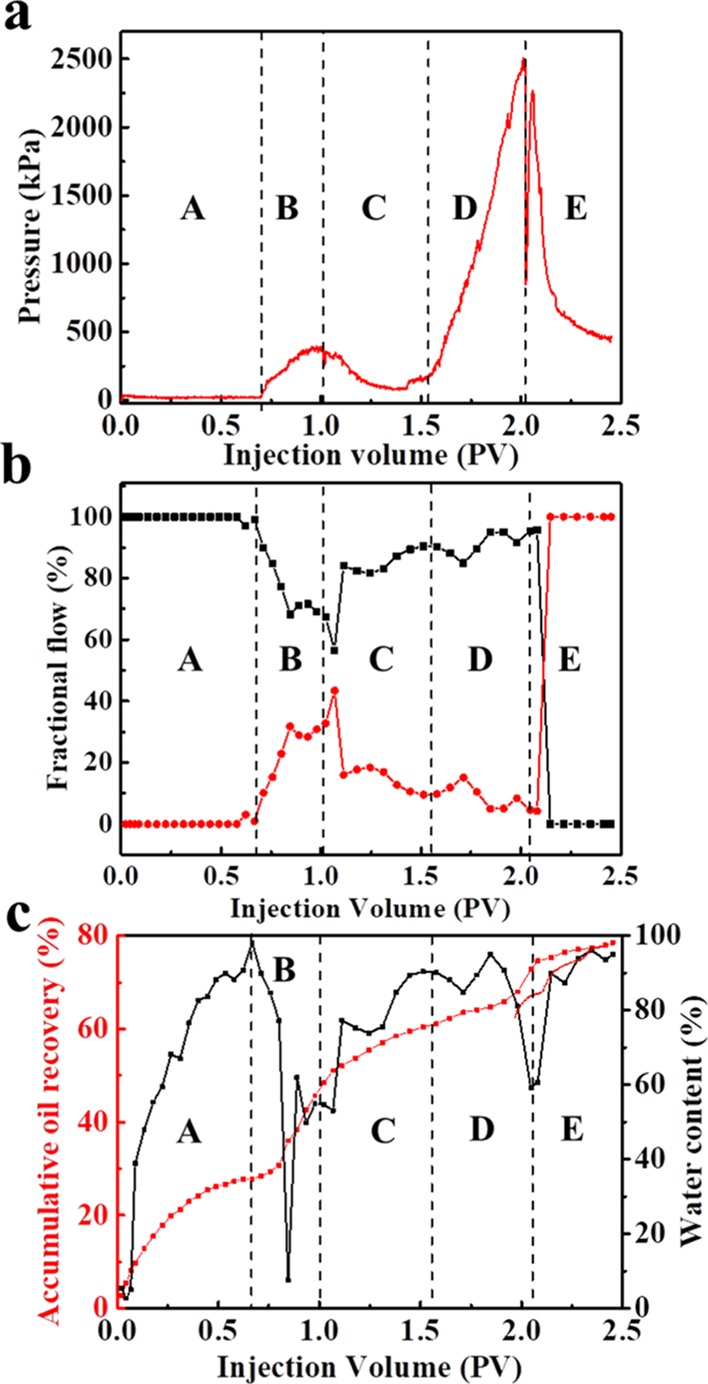

Parallel cores with a permeability ratio of 0.3:0.9 μm2 were saturated with oil, the viscosity of which was 9.8 mPa·s, as simulated in Figure 4A. Initial oil saturation (So) values of high and low permeability cores were 74.45 and 77.5%, respectively (Table 2). Displacement experiments underwent water-, polymer-, second water-flooding, gelant-injection, and last water-flooding, and the results are presented in Table 2 and Figure 5. The pressure curve fluctuated with various injecting fluids and pore volumes, and it kept a low pressure of approximately 30 kPa during the first water-flooding (Figure 5a). Fractional flow curves (black in Figure 5b) revealed that over 95% water flowed into the high permeability core for sweeping (Figure 4B), and the oil recovery through water-flooding (Rw) was 52.42% (Table 2 and red in Figure 5c). Less than 5% of chase water entered the low permeability channel (red in Figure 5b), and the resulted Rw was merely 4%. As a result, for heterogeneous reservoirs with a low permeability ratio, sole water-flooding played a significant part in the high permeability zone but resulted in extremely low Rw on the low permeability layer because of high flowing resistance. Water cut during the first water-flooding was up to 95% (red in Figure 5b). The 0.5 PV polymer of 1000 mg/L was injected, followed by the second water-flooding. Up to 40% polymer flowed into the low permeability core for displacing the residual oil because of the increase in the mobility ratio. Therefore, Table 2 shows that Rpw in the low permeability core increased to 49.64%, compared to Rpw of 18.6% in the high zone. The comparison indicated that polymer functioned excellent as profile modification in heterogeneous reservoirs with a low contrast coefficient of 1:3. Later, the chase water gradually detoured to the high permeability zone. When the water cutting increased, a gelant slug of 0.5 PV was injected. The parallel core was kept gelling under 45 °C for 12 days. Following this, third water-flooding was conducted for oil recovery after hydrogel treatment (Figure 4C). Figure 5a shows that the pressure sharply increased to 2500 kPa during the process of gelant injection, and the subsequent sweeping pressure also increased to 2300 kPa, suggesting the reasonable injection of gelant and formation of the hydrogel. As shown in the fractional flow curves, more than 90% of the chase water entered the low permeability core (red in Figure 5b), confirming the plugging of the delayed hydrogel in the high permeability zone. As a result, partial residual oil left in the low and high permeability zones were further recovered, and RGw was 20.82 and 14.34%, respectively. Undoubtedly, owing to low resistance, the injected gelant preferentially entered and plugged the high permeability core, so that the chase water was able to displace the abundant residual oil in low permeability (Figure 4D). The water cutting decreased by 35% because of the hydrogel technique (Figure 5c).

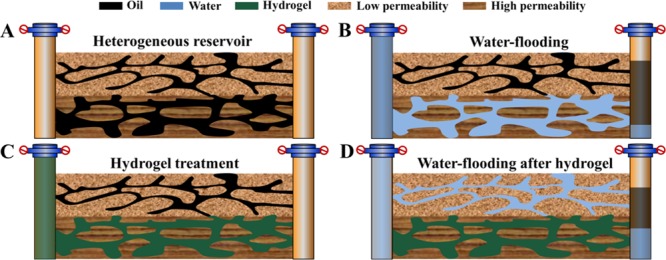

Figure 4.

Schematic of different displacement stages in a heterogeneous reservoir. (A) Oil-rich heterogeneous layers, (B) initial water-flooding, (C) hydrogel treatment for plugging high permeability zone, and (D) water-flooding after hydrogel treatment.

Figure 5.

(a) Pressure curve as the function of injection volume in the low-permeability-ratio double-core, (b) relationship between fractional flow and the injection volume, (c) accumulative oil recovery and water cut versus the injection volume. (A: first water-flooding, B: polymer injection, C: second water-flooding, D: gelant injection and gelation, and E: third water-flooding).

Permeability Contrast of 1:10

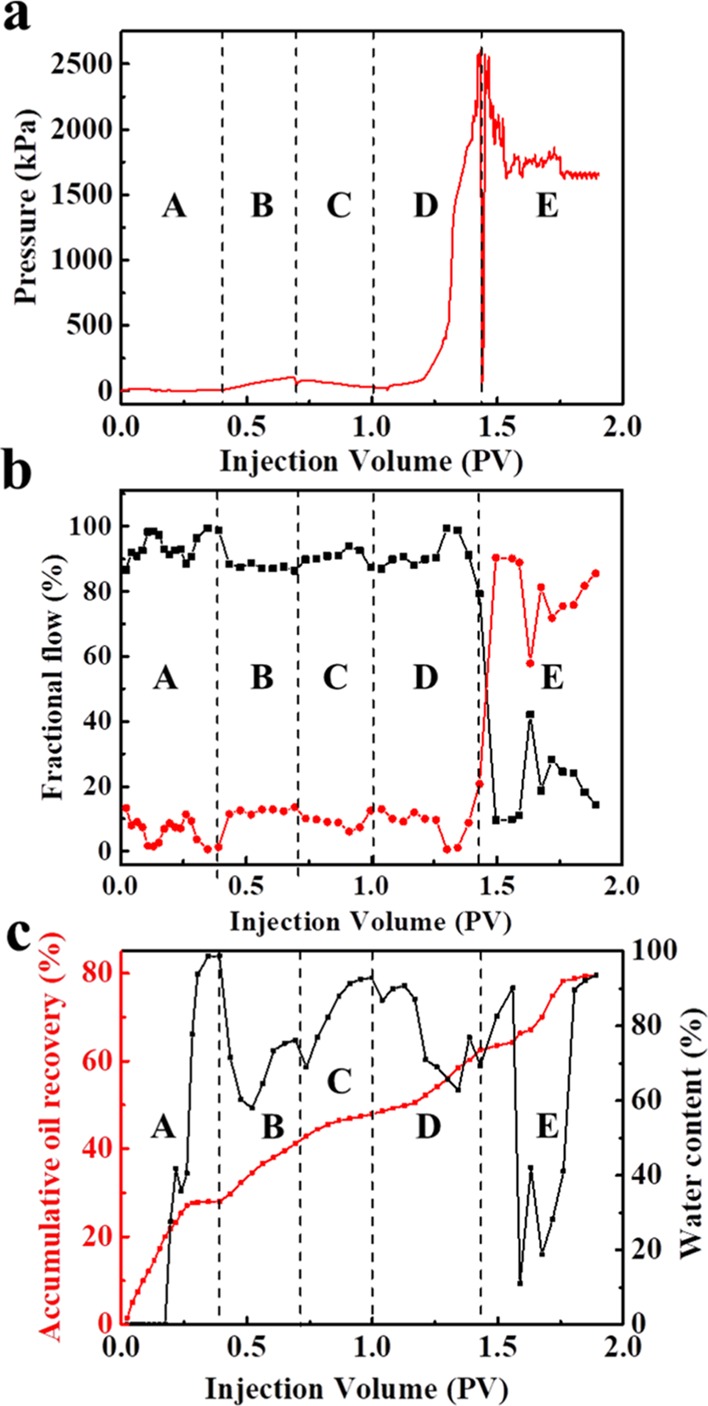

To further investigate the plugging capacity of the hydrogel especially after polymer-flooding, a parallel core with a medium permeability ratio of 0.3:3.0 μm2 was utilized for displacement tests. Oil recovery of the first water-flooding (Rw) in the low permeability core was 6.01% compared to high Rw of 48.91% in the high permeability core. Evidently, large amounts of chase water entered large channels of 3.0 μm2 (Figure 6b). For the following injection of the polymer, the pressure increased to 107 kPa (Figure 6a), much higher than that of water-flooding, but lower than that of the same procedure (378 kPa) in the low permeability ratio of 1:3 (Figure 5a). Fractional flowing improved little compared to the initial water-flooding, and the chase water still kept flowing into the large channels, which is significantly different from the improvement after polymer injection in the low permeability ratio layer of 1:3 where more water entered the low permeability layer (Figure 5b).

Figure 6.

(a) Pressure curve as the function of injection volume in the medium-permeability-ratio double-core, (b) relationship between fractional flow and the injection volume, (c) water cut and accumulative oil recovery vs the injection volume. (A: first water-flooding, B: polymer-injection, C: second water-flooding, D: gelant-injection and gelation, and E: third water-flooding).

As a result, Rpw in the low permeability core increased to 18.62% from 6.01% (Rw), which is much lower than the high efficiency of 49.64%, operated in the low permeability ratio of 1:3. Contributing a higher oil recovery than water-flooding, polymer-flooding functioned better at the low-permeability-ratio layers of 1:3 over the medium of 1:10. To increase the recovery efficiency in the low permeability core, hydrogel treatment was implemented. A high water-flooding pressure of 2500 kPa after the hydrogel-treatment is displayed in Figure 6a, and it is concluded that the hydrogel slug formed and plugged the large channel. As observed from the fractional flow curve, 80% chase water rapidly diverted the orientation to the low permeability core (Figure 6b). Water content significantly dropped to approximately 10% (Figure 6c), and oil recovery (RGw) in the low permeability core increased to 48.42%, compared to Rpw of 18.62%. Unlike 17.4% in the low permeability contrast of 1:3, the total EOR in the medium permeability ratio of 1:10 was 33.19% (Table 2). The comparison distinctly indicated that the delayed hydrogel technique conducted in the medium-permeability-ratio heterogeneous layer had evident superiority over the zones with a low-permeability-contrast, whereas polymer-flooding would improve recovery efficiency at the low permeability ratio heterogeneous zone.

Permeability Contrast of 1:15

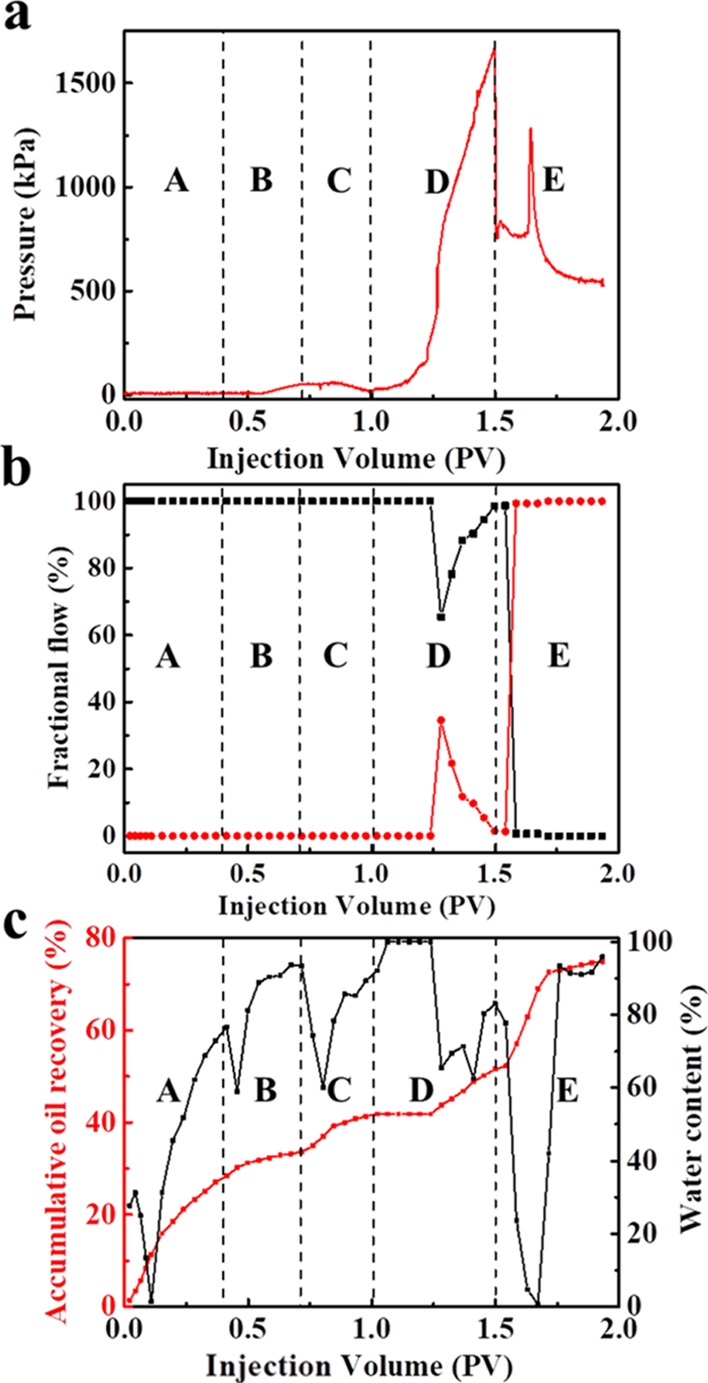

Parallel cores with a large permeability ratio of 0.3:4.5 μm2 were utilized to inspect the EOR efficiency of the delayed hydrogel treatment. Similar to those at the low and medium permeability ratio cores, the pressure in Figure 7a showed an apparent increase in both processes of gelant injection and the subsequent water-flooding. Clearly, 100% chase water entered into the high permeability core before hydrogel-treatment (Figure 7b) with no chase fluid sweeping the low permeability zone. Rw and Rpw in low permeability layers in Table 2 were both zero. Conventional polymer-flooding was capable of improving the sweeping area, but it did not function at all. Also, severe water circulation occurred, and the water cut even reached 99% (Figure 7c). Because of the hydrogel treatment, the fractional flow curve showed that over 90% chase water diverted to the low permeability core, where the previously unswept residual oil was displaced. Therefore, RGw in the low permeability core increased to 59.9% (Table 2) compared to 10.9% in the high permeability zone. Meanwhile, during the third water-flooding stage, the water cut significantly decreased from 80 to 0% (Figure 7c), illustrating that the enriched oil left in the low permeability zone was swept out. For the heterogeneous zone with a large permeability ratio of 1:15, the oil recovery was enhanced by 33.42% (Table 2) owing to the follow-up hydrogel treatment after polymer-flooding.

Figure 7.

(a) Pressure curve as the function of injection volume in the high-permeability-ratio double-core, (b) relationship between fractional flow and the injection volume, (c) water cutting and accumulative oil recovery versus the injection volume. (A: firstst water-flooding, B: polymer-injection, C: second water-flooding, D: gelant-injection and gelation, E: third water-flooding).

Further, RGw of the low permeability core with a ratio of 1:3 was much lower than that in both medium and high contrasts of 1:10 and 1:15, confirming the outstanding profile control and water shutoff of the delayed hydrogel in heterogeneous reservoirs having medium and high permeability ratios.

Conclusions

In conclusion, the delayed cross-linked PAM hydrogel technique after polymer flooding displayed distinct advantages while applied in heterogeneous reservoirs with large permeability ratios for EOR. Based on the study, the major summaries can be drawn: (i) Cr(III) established coordination cross-linking with HPAM resulting in delayed gelation over 10 days, exhibiting excellent in-depth plugging to avoid the detouring of the follow-up chase water. Suitability tests and single sand-pack models proved the well-adaptation of the gelant to achieve efficient profile modification for differential permeability layers. (ii) PAM-delayed hydrogels possessed high viscoelasticity and yield stress, being capable of sustaining shear and extrusion deformation during migration for sweeping. Exhibiting a dense structural framework, hydrogels provided a favorable elastic intensity for steady plugging large channels. (iii) Parallel-core displacing tests supported the fact that polymer-flooding functioned better as a profile modification and oil-displacing agent for heterogeneous layers having low permeability ratios, whereas for medium-permeability-contrast and large-permeability-contrast (≥10) zones, delayed hydrogel treatment extracted far more residual oil. The displacement models provided favorable guidance for in situ industrial production in heterogeneous oilfields.

Experimental Section

Materials

Partially hydrolyzed polyacrylamide (HPAM) AN905 with a molecular weight of 8 × 106 to 107 and a hydrolysis degree of 5% was purchased from SNF flocculant (France), and chromium(III) acetate was purchased from Laize Chemicals (China). Thiourea was provided from Oriental Chemicals (China). Crude oil was obtained from Daqing Oilfield, China, with a viscosity of 9.8 mPa·s at 45 °C. The simulated aqueous solution with a salinity of 5196.28 mg/L for gelant preparation was supplied from Daqing Oilfield, and its general formula is given in Table 3.

Table 3. Formula of Simulated Water.

| ions | Na+ | Ca2+ | Mg2+ | Cl– | CO32– | HCO3– | SO42– |

|---|---|---|---|---|---|---|---|

| content (mg/L) | 1686.89 | 0.72 | 0.83 | 1214.37 | 96.79 | 2196.00 | 0.68 |

Preparation of Polymer Hydrogel

PAM powder (0.5 g) was slowly dissolved in the simulated aqueous solution under stirring for 4 h to obtain a homogenous solution, and 0.5 mL of 10 wt % chromium(III) acetate cross-linker and 0.4 mL of 5 wt % thiourea were added dropwise into the previous suspension by stirring again for 30 min. The gelant was well-prepared and further placed under 45 °C for gelling. The polymer and cross-linker concentration was kept at 0.5 and 0.05 wt %, respectively.

Rheological Measurements

Rheological properties of the hydrogels were performed using a German HAAKE RS600 rheometer. Rheological behaviors of polymers and hydrogels were characterized using a Z41-Ti coaxial cylinder and PP20 plate-to-plate geometry sensors, respectively. The tests were first set in a stress oscillation scanning model with a stress range of 1–100 Pa and a shear rate of 1 Hz to obtain a linear viscoelastic region, in which a fixed stress of 4 Pa was ascertained. The subsequent viscoelasticity and yield tests were executed as a function of frequency ranging from 0.01 to 10 Hz. The tests were all carried out at 45 °C.

Environmental Scanning Electron Microscopy

Environmental scanning electron microscopy was performed using a quanta 200F microscope (American FEI) to observe morphologies of both HPAM and the hydrogel. An annular gaseous secondary electron detector was subjected to a vacuum degree of 267 Pa. Samples of 0.10 mL fluid or soybean-size hydrogels were initially placed into the three cylindrical grooves of a copper cylinder, which were further frozen to −60 °C using liquid nitrogen. The copper cylinder loading samples were put into the sample cell for vacuuming. Observations were performed along with the slow sublimation of the icy samples.

Flow and Displacement Experiment

Single Sand-pack Plugging Tests

The single sand-pack tests were conducted under a constant flow rate of 0.40 mL/min at 45 °C, while the water-flooding, polymer-flooding, and gelant injection were operated in turns. During the entire operation, water-flooding was initially completed to achieve a stable pressure, followed by the injections of 0.5 PV polymer, the second chase water, 0.7 PV gelant, and the third follow-up water. The final water injection was not performed until the gelant completely gelatinized.

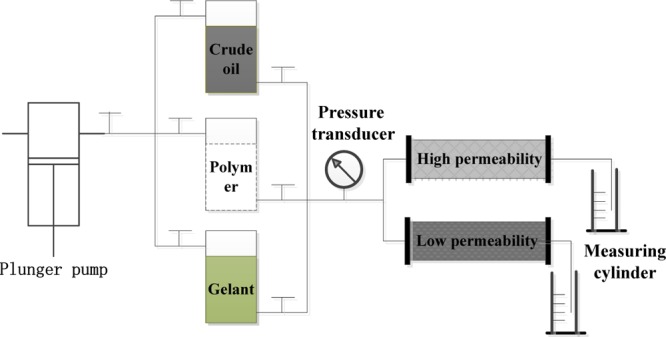

Double-Core Displacement Tests

Figure 8 shows the schematic device of the parallel core flow tests as given in ref (9). The experiments were carried out at a constant flow rate of 0.40 mL/min under 45 °C. Water-flooding was performed to measure the permeability of the cores, and the cores were both saturated with crude oil, followed by polymer, second water-flooding, gelant injection, third water driven, and fourth water-flooding. The process of water driven was run to impel the gelant to the depth of the cores. The fourth water-flooding was conducted for oil recovery after hydrogel treatment.

Figure 8.

Schematic of parallel sand-pack tests.

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (grant 51374219) and the National Key Scientific and Technological Project (grant no. 2017ZX05009-004).

The authors declare no competing financial interest.

References

- Gong H.; Xin X.; Xu G.; Wang Y. The dynamic interfacial tension between HPAM/C17H33COONa mixed solution and crude oil in the presence of sodium halide. Colloids Surf., A 2008, 317, 522–527. 10.1016/j.colsurfa.2007.11.034. [DOI] [Google Scholar]

- Pereira J. F. B.; Costa R.; Foios N.; Coutinho J. A. P. Ionic liquid enhanced oil recovery in sand-pack columns. Fuel 2014, 134, 196–200. 10.1016/j.fuel.2014.05.055. [DOI] [Google Scholar]

- Son H. A.; Yoon K. Y.; Lee G. J.; Cho J. W.; Choi S. K.; Kim J. W.; Im K. C.; Kim H. T.; Lee K. S.; Sung W. M. The potential applications in oil recovery with silica nanoparticle and polyvinyl alcohol stabilized emulsion. J. Pet. Sci. Eng. 2015, 126, 152–161. 10.1016/j.petrol.2014.11.001. [DOI] [Google Scholar]

- Jang H. Y.; Zhang K.; Chon B. H.; Choi H. J. Enhanced oil recovery performance and viscosity characteristics of polysaccharide xanthan gum solution. J. Ind. Eng. Chem. 2015, 21, 741–745. 10.1016/j.jiec.2014.04.005. [DOI] [Google Scholar]

- Samanta A.; Bera A.; Ojha K.; Mandal A. Effects of Alkali, Salts, and Surfactant on Rheological Behavior of Partially Hydrolyzed Polyacrylamide Solutions†. J. Chem. Eng. Data 2010, 55, 4315–4322. 10.1021/je100458a. [DOI] [Google Scholar]

- Mohajeri M.; Hemmati M.; Shekarabi A. S. An experimental study on using a nanosurfactant in an EOR process of heavy oil in a fractured micromodel. J. Pet. Sci. Eng. 2015, 126, 162–173. 10.1016/j.petrol.2014.11.012. [DOI] [Google Scholar]

- Muggeridge A.; Cockin A.; Webb K. J.; Harry Frampton H.; Collins I. R.; Moulds T.; Salino P. Recovery rates, enhanced oil recovery and technological limits. Philos. Trans. R. Soc., A 2014, 372, 20120320. 10.1098/rsta.2012.0320. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Gharbi R. B. C. An expert system for selecting and designing EOR processes. J. Pet. Sci. Eng. 2000, 27, 33–47. 10.1016/s0920-4105(00)00049-8. [DOI] [Google Scholar]

- Sang Q.; Li Y.; Yu L.; Li Z.; Dong M. Enhanced oil recovery by branched-preformed particle gel injection in parallel-sandpack models. Fuel 2014, 136, 295–306. 10.1016/j.fuel.2014.07.065. [DOI] [Google Scholar]

- Root P. J.; Skiba F. F. Crossflow Effects During an Idealized Displacement Process In a Stratified Reservoir. Soc. Pet. Eng. J. 1965, 5, 229–238. 10.2118/958-pa. [DOI] [Google Scholar]

- Scott T.; Roberts L. J.; Sharp S. R.; Clifford P. J.; Sorbie K. S. In-Situ Gel Calculations in Complex Reservoir Systems Using a New Chemical Flood Simulator. SPE Reserv. Eng. 1987, 2, 634–646. 10.2118/14234-pa. [DOI] [Google Scholar]

- Wang Y.; Bai B.; Gao H.; He L.; Zhao F.. Enhanced Oil Production Through a Combined Application of Gel Treatment and surfactant huff’n’puff technology. SPE International Symposium and Exhibition on Formation Damage Control, Jan 1, 2008.

- Thomas F. B.; Bennion D. B.; Anderson G. E.; Meldrum B. T.; Heaven W. J. Water Shut-off Treatments-Reduce Water and Accelerate Oil Production. J. Can. Pet. Technol. 2000, 39, 25–29. 10.2118/00-04-TN. [DOI] [Google Scholar]

- Zitha P. L. J.; Darwish M. M. I.. Effect of Bridging Adsorption on the Placement of Gels for Water Control. SPE Asia Pacific Improved Oil Recovery Conference, Jan 1, 1999.

- Al-Muntasheri G. A.; Zitha P. L. J.. Gel under Dynamic Stress in Porous Media: New Insights using Computed Tomography. SPE Saudi Arabia Section Technical Symposium, Jan 1, 2009.

- Wu Y.; Tang T.; Bai B.; Tang X.; Wang J.; Liu Y. An Experimental Study of Interaction Between Surfactant and Particle Hydrogels. Polymer 2011, 52, 452–460. 10.1016/j.polymer.2010.12.003. [DOI] [Google Scholar]

- Jia H.; Pu W.-F.; Zhao J.-Z.; Liao R. Experimental Investigation of the Novel Phenol–Formaldehyde Cross-Linking HPAM Gel System: Based on the Secondary Cross-Linking Method of Organic Cross-Linkers and Its Gelation Performance Study after Flowing through Porous Media. Energy Fuels 2011, 25, 727–736. 10.1021/ef101334y. [DOI] [Google Scholar]

- Goudarzi A.; Zhang H.; Varavei A.; Taksaudom P.; Hu Y.; Delshad M.; Bai B.; Sepehrnoori K. A laboratory and simulation study of preformed particle gels for water conformance control. Fuel 2015, 140, 502–513. 10.1016/j.fuel.2014.09.081. [DOI] [Google Scholar]

- Imqam A.; Bai B. Optimizing the strength and size of preformed particle gels for better conformance control treatment. Fuel 2015, 148, 178–185. 10.1016/j.fuel.2015.01.022. [DOI] [Google Scholar]

- Chen Z.; Schuman T. P.; Geng J.; Bai B. Water-free synthesis of temperature-sensitive polyacrylamide microgels and pore modeled oil recovery performance. J. Appl. Polym. Sci. 2017, 134, 44581. 10.1002/app.44581. [DOI] [Google Scholar]

- Elsharafi M. O.; Bai B. Effect of Weak Preformed Particle Gel on Unswept Oil Zones/Areas during Conformance Control Treatments. Ind. Eng. Chem. Res. 2012, 51, 11547–11554. 10.1021/ie3007227. [DOI] [Google Scholar]

- Liu Y.; Bai B.; Wang Y. Applied technologies and prospects of conformance control treatments in China. Oil Gas Sci. Technol.-Rev. Inst. Fr. Du Pet. 2010, 65, 859–878. 10.2516/ogst/2009057. [DOI] [Google Scholar]

- Tongwa P.; Nygaard R.; Bai B. Evaluation of a nanocomposite hydrogel for water shut-off in enhanced oil recovery applications: Design, synthesis, and characterization. J. Appl. Polym. Sci. 2013, 128, 787–794. 10.1002/app.38258. [DOI] [Google Scholar]

- Zolfaghari R.; Katbab A. A.; Tabasi R. Y.; Nejad M. H. Preparation and characterization of nanocomposite hydrogels based on polyacrylamide for enhanced oil recovery applications. J. Appl. Polym. Sci. 2006, 100, 2096–2103. 10.1002/app.23193. [DOI] [Google Scholar]

- Chen L.; Zhu X.; Fu M.; Zhao H.; Li G.; Zuo J. Experimental study of calcium-enhancing terpolymer hydrogel for improved oil recovery in ultrodeep carbonate reservoir. Colloids Surf., A 2019, 570, 251–259. 10.1016/j.colsurfa.2019.03.025. [DOI] [Google Scholar]

- Wang L.; Geng J.; Bai B. Highly Deformable Nano-Cross-Linker-Bridged Nanocomposite Hydrogels for Water Management of Oil Recovery. Energy Fuels 2018, 32, 3068–3076. 10.1021/acs.energyfuels.7b03649. [DOI] [Google Scholar]

- Chen L.; Zhang G.; Ge J.; Jiang P.; Zhu X.; Ran Y.; Han S. Ultrastable Hydrogel for Enhanced Oil Recovery Based on Double-Groups Cross-Linking. Energy Fuels 2015, 29, 7196–7203. 10.1021/acs.energyfuels.5b02124. [DOI] [Google Scholar]

- El-hoshoudy A. N.; Mohammedy M. M.; Ramzi M.; Desouky S. M.; Attia A. M. Experimental, modeling and simulation investigations of a novel surfmer-co-poly acrylates crosslinked hydrogels for water shut-off and improved oil recovery. J. Mol. Liq. 2019, 277, 142–156. 10.1016/j.molliq.2018.12.073. [DOI] [Google Scholar]

- Singh R.; Mahto V.; Vuthaluru H. Development of a novel fly ash-polyacrylamide nanocomposite gel system for improved recovery of oil from heterogeneous reservoir. J. Pet. Sci. Eng. 2018, 165, 325–331. 10.1016/j.petrol.2018.02.038. [DOI] [Google Scholar]

- Tessarolli F. G. C.; Gomes A. S.; Mansur C. R. E.. Hydrogels Applied for Conformance-Improvement Treatment of Oil Reservoirs. In Hydrogels, Haider S., Haider A.; Intechopen Limited: London, United Kingdom, 2018; Chapter 9, pp 69–87. [Google Scholar]

- Wu J.; Wang H.-F.; Wang X.-B.; Yang H.-Y.; Jiang R.-Y.; Zeng R. J. Design and characterization of a microbial self-healing gel for enhanced oil recovery. RSC Adv. 2017, 7, 2578–2586. 10.1039/c6ra25814j. [DOI] [Google Scholar]

- Li Q.; Wei B.; Lu L.; Li Y.; Wen Y.; Pu W.; Li H.; Wang C. Investigation of physical properties and displacement mechanisms of surface-grafted nano-cellulose fluids for enhanced oil recovery. Fuel 2017, 207, 352–364. 10.1016/j.fuel.2017.06.103. [DOI] [Google Scholar]

- Wang L.; Long Y.; Ding H.; Geng J.; Bai B. Mechanically robust re-crosslinkable polymeric hydrogels for water management of void space conduits containing reservoirs. Chem. Eng. J. 2017, 317, 952–960. 10.1016/j.cej.2017.02.140. [DOI] [Google Scholar]

- Pu J.; Zhou J.; Chen Y.; Bai B. Development of Thermotransformable Controlled Hydrogel for Enhancing Oil Recovery. Energy Fuels 2017, 31, 13600–13609. 10.1021/acs.energyfuels.7b03202. [DOI] [Google Scholar]

- You Q.; Zhao F. Research and application of deep plugging water in oil well. Drill. Prod. Technol. 2007, 30, 85. [Google Scholar]

- Dong X.; Jia X.; Yuan H.; Yang H.; He J. Research and application of injection well deep plugging technology in fractured reservoir. Petrochem. Ind. Appl. 2009, 8, 017. [Google Scholar]

- Zhao G.; Dai C.; Cheng M. Study on the In-Depth Profile Control Technology of Weak Gels for Low Permeability Reservoir in Shinan 21 Well Area. Chem. Eng. Oil Gas 2011, 40, 594–597. [Google Scholar]

- Albonico P.; Burrafato G.; Di Lullo A.; Lockhart T. P.. Effective Gelation-Delaying Additives for Cr+3/Polymer Gels. SPE International Symposium on Oilfield Chemistry, Jan 1, 1993.

- Cordova M.; Cheng M.; Trejo J.; Johnson S. J.; Willhite G. P.; Liang J.-T.; Berkland C. Delayed HPAM Gelation via Transient Sequestration of Chromium in Polyelectrolyte Complex Nanoparticles. Macromolecules 2008, 41, 4398–4404. 10.1021/ma800211d. [DOI] [Google Scholar]

- Jayakumar S.; Lane R. H.. Delayed Crosslink Polymer Flowing Gel System for Water Shutoff in Conventional and Unconventional Oil and Gas Reservoirs. SPE International Symposium and Exhibition on Formation Damage Control, Jan 1, 2012.

- Jayakumar S.; Lane R. H.. Delayed Crosslink Polymer Flowing Gel System for Water Shutoff in Conventional and Unconventional Oil and Gas Reservoirs. SPE International Symposium and Exhibition on Formation Damage Control, Jan 1, 2012. [Google Scholar]

- Jung Y. C.; Sahoo N. G.; Cho J. W. Polymeric Nanocomposites of Polyurethane Block Copolymers and Functionalized Multi-Walled Carbon Nanotubes as Crosslinkers. Macromol. Rapid Commun. 2006, 27, 126–131. 10.1002/marc.200500658. [DOI] [Google Scholar]

- Baek S. H.; Kim B. K. Synthesis of polyacrylamide/polyurethane hydrogels by latex IPN and AB crosslinked polymers. Colloids Surf., A 2003, 220, 191–198. 10.1016/s0927-7757(03)00074-8. [DOI] [Google Scholar]

- Bao J.; Xu G.; Liu D.; Ji X. Synthesis of Waterborne Polyurethane-polyacrylamide IPN Biomedical Hydrogels. Chin. J. Appl. Chem. 2008, 25, 587–591. [Google Scholar]

- Xu B. Delayed crosslinking HPAM gel system based on competitive inclusion. AIP Conf. Proc. 2016, 1795, 020028. 10.1063/1.4971910. [DOI] [Google Scholar]

- Sun F.; Lin M.; Dong Z.; Zhu D.; Wang S. L.; Yang J. Effect of Composition of HPAM/Chromium(III) Acetate Gels on Delayed Gelation Time. J. Dispersion Sci. Technol. 2016, 37, 753–759. 10.1080/01932691.2015.1041034. [DOI] [Google Scholar]