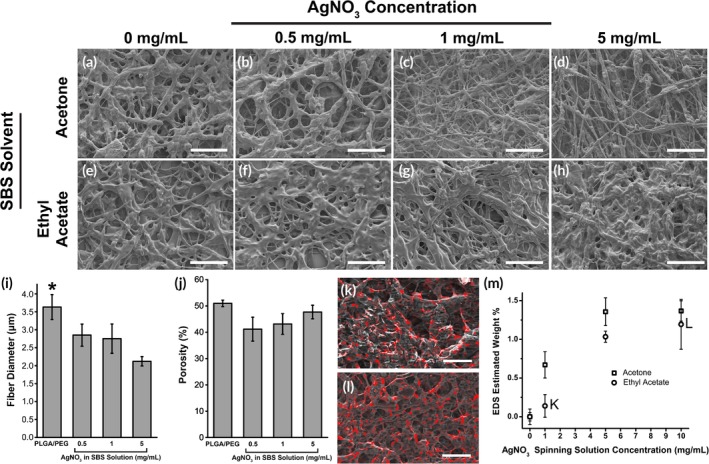

Figure 1.

SEM images of PLGA/PEG fibers produced using solution blow spinning with increasing concentrations of AgNO3 added to the spinning solution. Fibers produced using acetone as the spinning solvent (a–d) create a beads‐on‐a‐string morphology when loaded with AgNO3, while those made with ethyl acetate (e–h) have a consistent web‐like fiber morphology. Scale bar = 100 μm. When using ethyl acetate as the spinning solvent, there are decreases in fiber diameter with AgNO3 concentration (i), while porosity (j) is similar (n = 2–4). Energy dispersive x‐ray spectroscopy (EDS) shows that PLGA/PEG fibers produced using solution blow spinning with ethyl acetate contains silver. EDS signal (red) superimposed on scanning electron microscopy images of fibers produced from polymer solution containing 1 mg/mL (k) and 10 mg/mL (l) AgNO3. Scale bar = 10 μm. (m) Plot of estimated weight percent of silver calculated from EDS for PLGA/PEG spinning solutions varying in AgNO3 concentration. Asterisks indicate statistical significance: *p < .05; **p < .01; ***p < .001