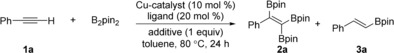

Table 1.

Optimization of the reaction conditions.[a]

|

Entry |

Catalyst |

Ligand |

Additive |

Yield 2 a [b] |

Yield 3 a |

|---|---|---|---|---|---|

|

1 |

Cu(OAc)2 |

PnBu3 |

iPr2EtN |

45 % (38 %[c]) |

32 % |

|

2 |

Cu(OTf)2 |

PnBu3 |

iPr2EtN |

0 % |

2 % |

|

3 |

CuCl2 |

PnBu3 |

iPr2EtN |

0 % |

0 % |

|

4c |

CuCl2 |

PnBu3 |

iPr2EtN |

42 % |

26 % |

|

5[c] |

CuCl |

PnBu3 |

iPr2EtN |

22 % |

34 % |

|

6 |

CuOAc |

PnBu3 |

iPr2EtN |

29 % |

20 % |

|

7 |

Cu(OAc)2 |

PPh3 |

iPr2EtN |

18 % |

40 % |

|

8 |

Cu(OAc)2 |

PCy3 |

iPr2EtN |

33 % |

23 % |

|

9 |

Cu(OAc)2 |

phen |

iPr2EtN |

trace |

8 % |

|

10 |

Cu(OAc)2 |

bpy |

iPr2EtN |

0 % |

4 % |

|

11[d] |

Cu(OAc)2 |

PnBu3 |

iPr2EtN |

14 % |

39 % |

|

12[e] |

Cu(OAc)2 |

PnBu3 |

iPr2EtN |

31 % |

18 % |

|

13 |

Cu(OAc)2 |

PnBu3 |

– |

28 % (16 %) |

28 % |

|

14 |

Cu(OAc)2 |

PnBu3 |

benzophenone |

48 % |

22 % |

|

15 |

Cu(OAc)2 |

PnBu3 |

2‐norbornene |

59 % (50 %) |

16 % |

|

16 |

Cu(OAc)2 |

PnBu3 |

acrylonitrile |

69 % (66 %) |

12 % |

|

17[f] |

Cu(OAc)2 |

PnBu3 |

acrylonitrile |

78 % (73 %) |

11 % |

|

18[f] |

Cu(OAc)2 |

– |

acrylonitrile |

0 % |

0 % |

|

19[f] |

– |

PnBu3 |

acrylonitrile |

0 % |

0 % |

[a] Reaction conditions: 1 a (0.2 mmol), B2pin2 (0.6 mmol), Cu catalyst (0.02 mmol), ligand (0.04 mmol), and additive (0.2 mmol) in toluene (2 mL) at 80 °C. [b] Yields were determined by GC/MS analysis with n‐dodecane as an internal calibration standard. Yields of isolated products are given in parentheses. [c] 20 mol % KOAc. [d] 60 °C. [e] 90 °C. [f] 4 h.