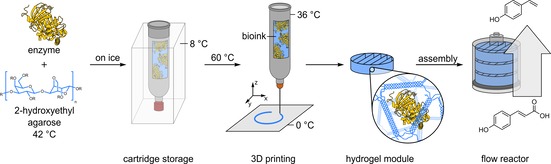

Figure 1.

Manufacturing process of agarose‐based, compartmentalized biocatalytic flow reactors. The enzyme is mixed with a liquid agarose solution (at 42 °C) and immediately cooled down on ice and then stored at 8 °C. Using a 3D printer, the bioink is melted at 60 °C and printed onto a cooled substrate on which the bioink solidifies to form biocatalytic modules. These are integrated into flow reactors that are transfused with a substrate solution to facilitate continuous synthesis. The reactor productivity can be adjusted by variable numbers of reaction modules.6