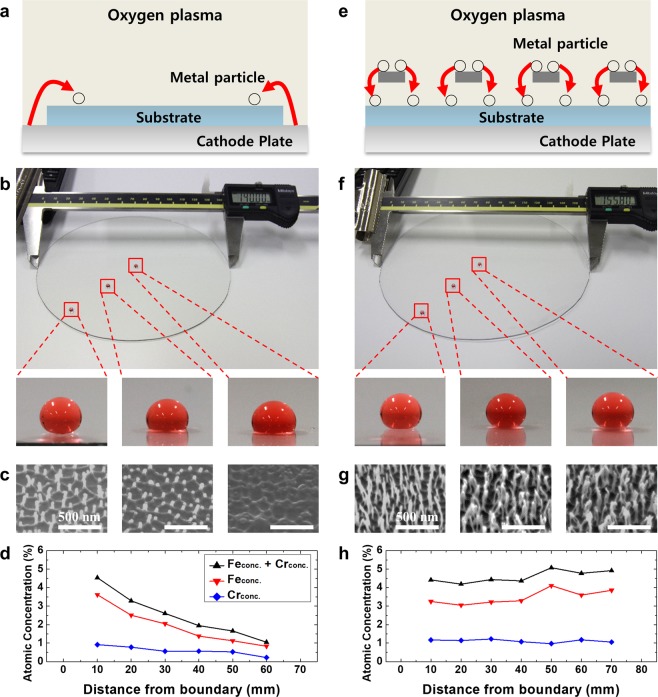

Figure 3.

(a) Schematic of conventional nanofabrication through O2 plasma preferential etching. Metal atoms are sputtered from the stainless-steel cathode plate and co-deposited on the substrate to act as a nanoscale etch mask. (b) Optical microscope images of water droplets on the three different spots on the plasma-treated PET substrate with a diameter of 140 mm. (c) SEM images of the three different spots on the substrate. (d) The atomic concentration of metal compounds on the plasma-treated substrate according to distance from the boundary. (e) Schematic of novel fabrication method assisted by metallic mesh overhung with D = 2 mm. Metal atoms are sputtered from the overhung mesh. (f) Water droplets with high CA on the three different spots on the plasma-treated PET substrate with a similar diameter of 155.8 mm. (g) SEM images of the three different spots on the substrate. (h) The atomic concentration of the metal compound on the plasma-treated substrate.