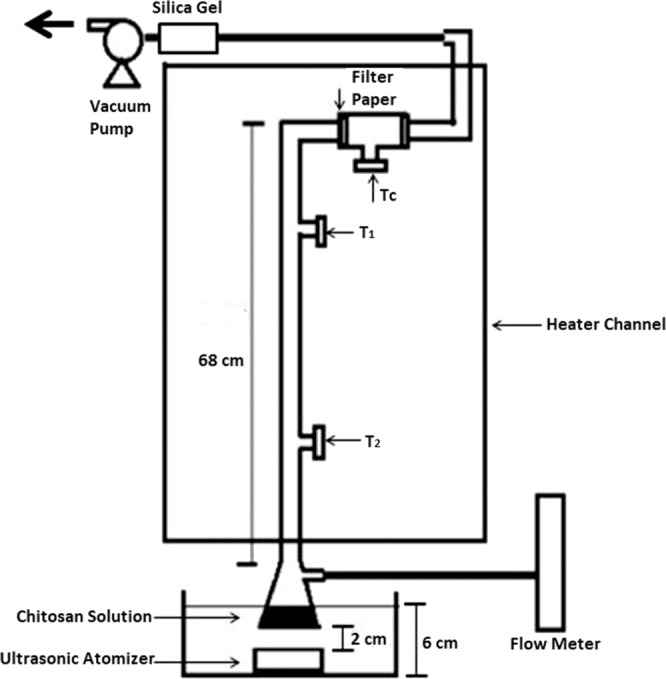

Figure 7.

Spray drying apparatus. The drops were produced in ultrasonic atomization from a precursor solution (i.e., formulated solution from sections 2.1 and 2.2) and then vacuumed pumped into the central channel at a constant airflow rate (measured from the flow meter). The drier was heated with a heater strip wrapping around the column, of which the temperature was controlled by a temperature controller with an indicator (TC) and monitored at T1 and T2 position. The atomized drops carried by an airflow were heated and dried when it passed through the heated column, then collected the dried particles on a silicon plate and a filter paper (5 C) from Advantec MFS, Inc (Dublin, CA, USA).