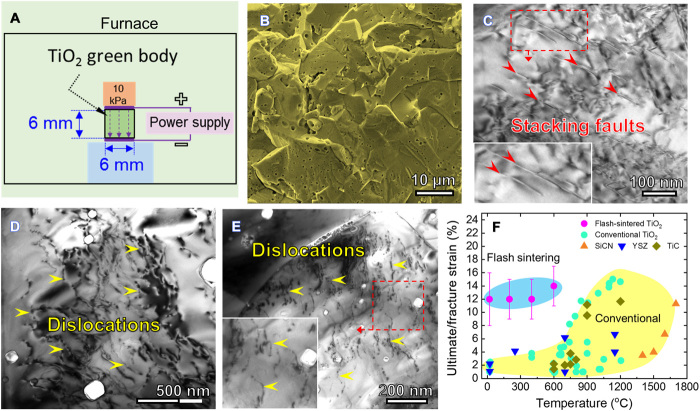

Fig. 1. Microstructures of TiO2 prepared by flash sintering and comparison of temperature-dependent deformability of flash-sintered TiO2 with other typical ceramic materials.

(A) Schematics of flash sintering of TiO2. (B) SEM image of the unpolished flash-sintered TiO2. (C) Bright-field TEM micrograph showing an area of the flash-sintered TiO2 containing stacking faults. (D and E) TEM micrographs showing high-density dislocations within TiO2 grains. (F) Ultimate/fracture strain (%) as a function of testing temperatures for flash-sintered TiO2, conventional TiO2 (28, 30), and other conventional ceramic systems, including SiCN (31), YSZ (32), and TiC (33). Fracture strain is very low at low temperatures and increases with temperatures for most of the conventional ceramics. However, the flash-sintered TiO2 exhibits significantly enhanced deformability even at RT (solid magenta circle data points).