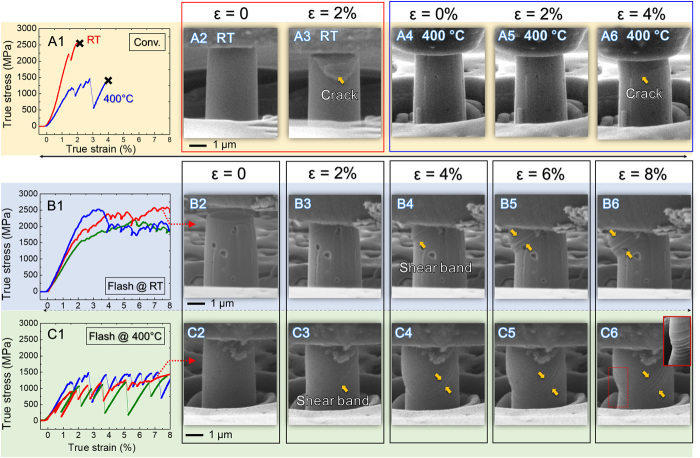

Fig. 2. Uniaxial in situ microcompression tests on the conventional and flash-sintered TiO2 at different temperatures, RT versus 400°C, at a constant strain rate of 5 × 10−3 s−1.

(A1 to A6) Representative stress-strain curves of conventional sintered TiO2 tested at RT and 400°C; all pillars experienced brittle catastrophic fractures at an average true strain of 2% for RT tests and 3% for 400°C tests. (B1 to B6) Stress-strain curves of flash-sintered TiO2 tested at RT showing work hardening to a maximum flow stress of 2 to 2.5 GPa and relatively continuous flow stress-strain curves with small serrations. Stress-strain curves of different colors were obtained from different individual pillars. The in situ movie SEM snapshots of a pillar (red data in Fig. 2B1) compressed to different strain levels show the formation of successive high-density slip bands. No fracture was observed up to a strain of 8%. (C1 to C6) At 400°C, large isolated serrations manifested by sharp load-drops were observed. Each load-drop usually corresponds to the formation of a major shear band as indicated by arrows. The inset of (C6) shows a magnified view of multiple shear bands generated during deformation (see movies S1 and S2 for more details on conventional sintered pillars and movies S5 and S6 for more details on flash-sintered pillars).