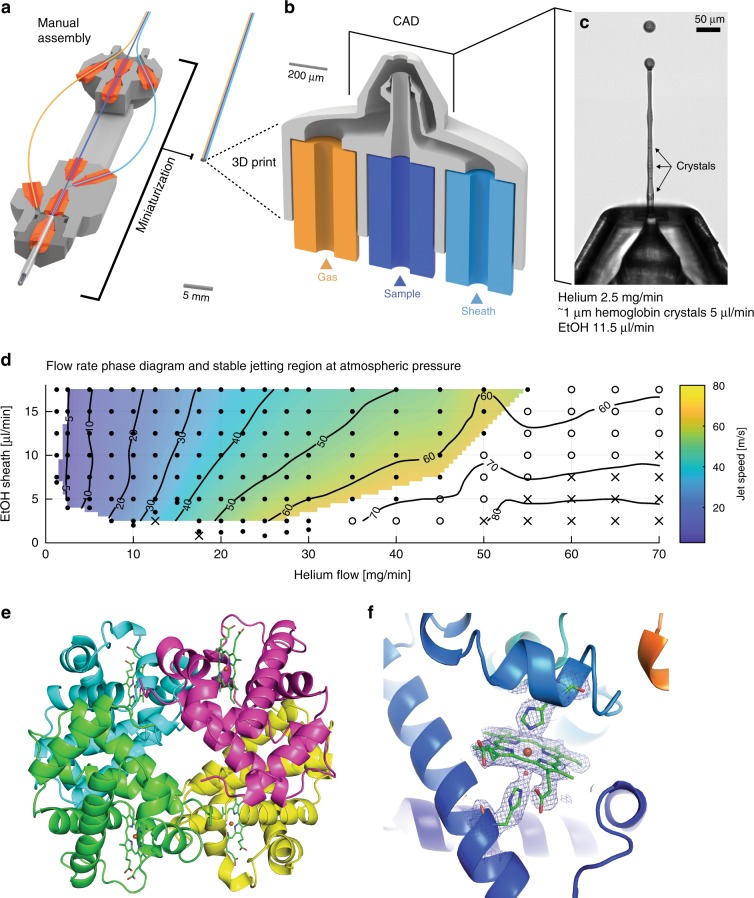

Fig. 4. Double-flow-focusing GDVN as a versatile low consumption injector.

a Three-dimensional (3D) printing facilitates fabrication of intricate structures that are difficult or impossible to manufacture otherwise. The manual DFFN design assembles three polished glass capillary orifices into a machined 10 cm long aluminum body, which we compress into a single integrated piece of <1 mm in size. b Three-dimensional (3D) DFFN CAD design with three capillary inlets featuring a 75 µm inner diameter liquid and a 70 µm diameter gas orifice. The sheath liquid channel circumvents the sample line close to the nozzle tip to prevent interferences from stagnating gas bubbles. c Approximately 3 μm sized Hemoglobin crystals are visible in the liquid jet (SI Movie 6). d 3D DFFN stable jetting phase diagram under atmospheric pressure. In air, liquid jets continue to accelerate after exiting the gas orifice since the focusing gas is kept compressed around the liquid jet due to the surrounding atmospheric pressure. Jet speeds were determined at 100 μm distance from the gas orifice by the polynomial fit of displaced particles using dual pulse iLIF (Supplementary Fig. 3). The design achieved stable jet speeds ranging from 3 m s−1 up to 60 m s−1 and jet speeds were proportional to the applied focusing gas mass flow and inversely proportional to ethanol sheet liquid flow rate at constant liquid sample flow of 5 µl min−1. e Cartoon plot of the asymmetric unit and biological assembly of Hemoglobin refined against data recorded at MFX, LCLS. Different colors indicate the individual chains (α2β2), heme-groups are shown as sticks (green) with iron atoms colored in brown. f Shows electron density map (2Fo-Fc) around one heme-group and associated His-residues and one water molecule connecting His and Fe.