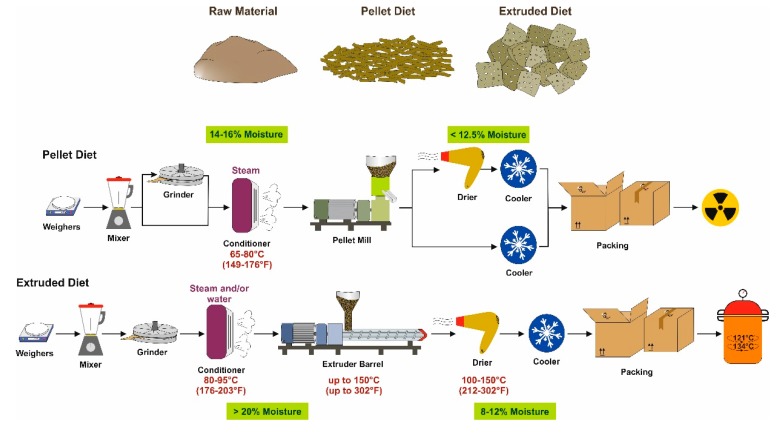

Figure 1.

Schematic overview about the production process of mouse diets. Pellet and extruded diets are produced from the same raw materials. In a first step, the different ingredients are put together in the intended proportion, mixed, grinded to the desired density, and moistened to a desired moisture content (pellet diets: ~14–16%; extruded diet: >20%). Pellet diet is then processed in a pellet mill and dependent on the water content included either directly cooled or dried to a moisture content lower 12.5%. Thereafter, this diet is packed and sterilized for example by irradiation. In contrast, during the production of an extruded diet, the conditioned materials are then forced through an opening of a perforated plate or die to create a product in desired shape and size. It is then dried to moisture content of 8–12%, cooled, and packed. These diets are more or less germ-free because of the high temperature in the extruder barrel and drier. If necessary, these diets can be further sterilized by autoclaving before use. However, the high temperature during the extruding process already warrants low concentrations of microorganisms.