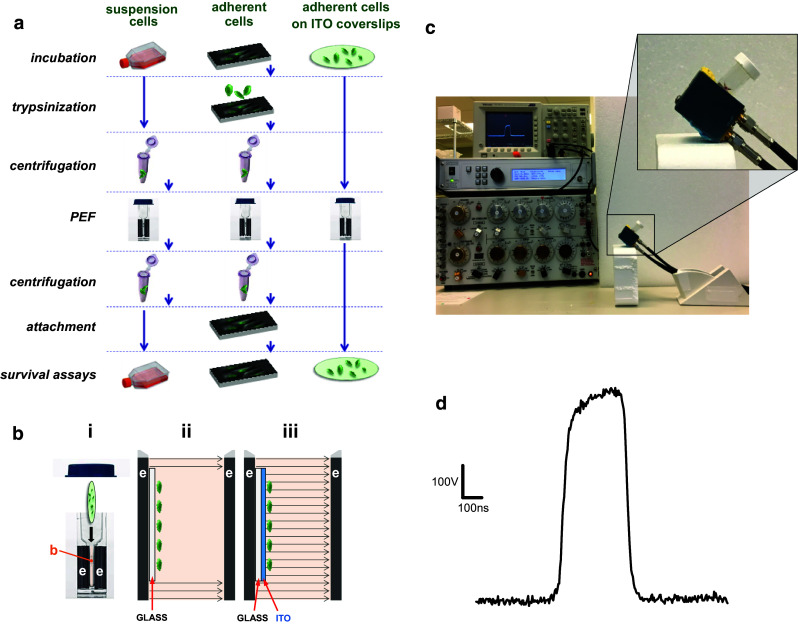

Fig. 1.

Streamlined pulsed electric field (PEF) treatment of adherent cells on coverslips with an electroconductive indium tin oxide (ITO) layer. a Standard sequence of procedures for PEF exposure in electroporation cuvettes for suspension-grown cells (left) and adherent cells (center). The use of ITO coverslips (right) eliminates multiple steps which may affect cell survival. b Schematic explaining PEF delivery to cells in an electroporation cuvette (i) with buffer (b) placed in a gap between two electrodes (e). Panels ii and iii show the enlarged view of this gap (not to scale) and the electric field lines when cells are attached to a “regular” glass coverslip (ii) or attached to an ITO-coated coverslip (iii). The regular glass coverslip shields cells from the electric field, whereas the ITO layer serves as an electrode and cancels shielding; see text for more details. c Exposure setup used in this study. The magnified area shows the electroporation cuvette tilted to keep the ITO coverslip resting flat on the bottom electrode. The ITO surface with cells is facing up into the medium. d Shape of a 300-ns pulse at 600 V (1.8 kV/cm)