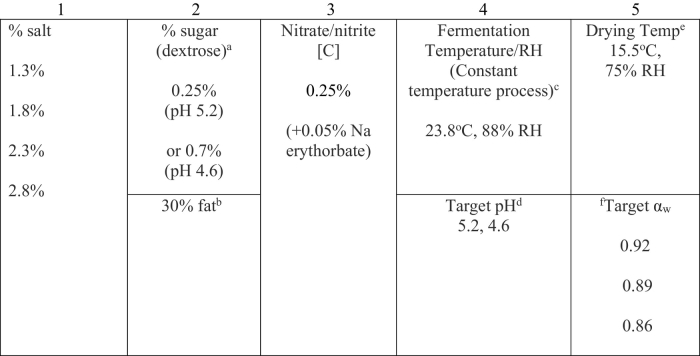

Table 1.

Curing Regimen for production of dry-cured sausage. Column 1: Four NaCl concentrations were used in batter formulations. Column 2a: Half of each preparation of salted batter were prepared with 0.7% dextrose, the other half was prepared with 0.25% dextrose. Added dextrose in the batter is fermented by added Pediococcus acidilactici and Staphylococcus carnosus lactobacillus, resulting in acidification of the batter matrix. The higher the dextrose concentration, the longer fermentation proceeds, resulting in a lower final pH. 2b: All batters were formulated with 30% pork back fat. Column 3: All batters were formulated with 0.25% sodium nitrate/nitrite curing salt as a preservative, and 0.05% sodium erythorbate to act as an antioxidant to preserve meat color and to accelerate the breakdown of sodium nitrate to nitrite by bacteria, speeding the curing process. Column 4c: All chubs were fermented at a constant temperature and RH of 23.8 °C and 88% RH. 4d: All chubs from each salt concentration prepared with 0.7% dextrose were fermented to pH 4.6, chubs prepared with 0.25% dextrose were fermented to pH 5.2. Column 5e: All chubs from each salt concentration and each pH were dried at 15.5 °C, 75% RH. 5f: Once chubs reached αw of 0.92, 0.89, or 0.86, meat from each chub was digested and inoculated into mice (n = 5) to determine continued viability of T. gondii present in meat.