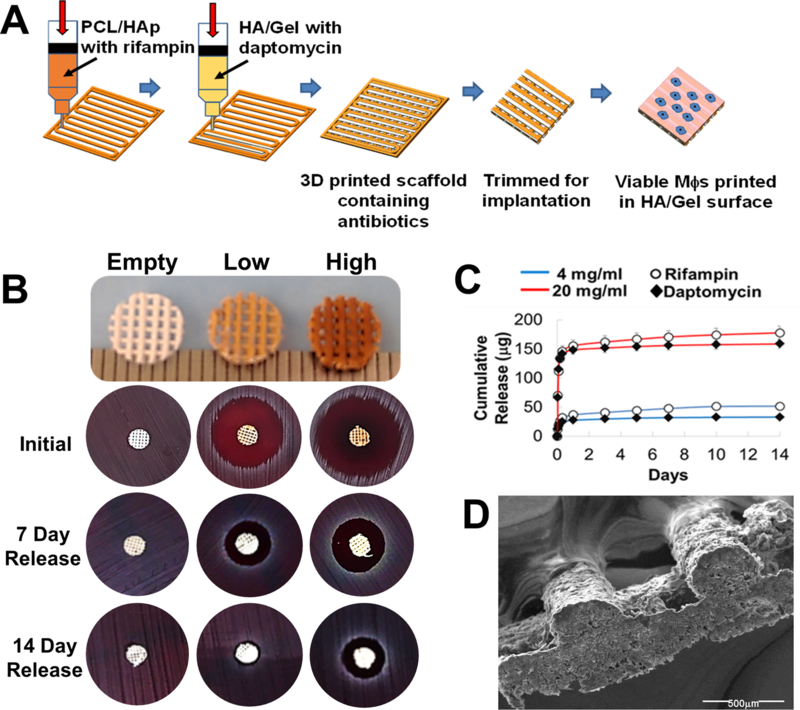

Figure 2. Release profile and bactericidal effect of 3D printed scaffolds containing daptomycin and rifampin.

(A) A polycaprolactone (PCL) (polyester) /hydroxyapatite (HAp) slurry was used to generate multiple PCL/HAp frames in each layer throughout the construct. Another printing head deposited hyaluronic acid (HA) and gelatin-based hydrogels between the PCL/HAp frames. Rifampin was incorporated in the PCL/HAp slurry and daptomycin was added to the HA/Gel hydrogel. Both low (~0.6 μg and 1.6 μg rifampin and daptomycin per mg scaffold, respectively) and high (~16 μg and 18 μg rifampin and daptomycin per mg scaffold, respectively) were examined. Once the antibiotic scaffold was dried, viable MΦs were printed on the surface in a HA/Gel hydrogel matrix and immediately implanted into mice. (B) Efficacy of 3D bioprinted scaffolds to kill a lawn of S. aureus when used fresh or after incubation in PBS for 7 or 14 days to simulate antibiotic release in vivo. (C) Quantitation of antibiotic release profile from 3D printed scaffolds over the course of 14 days in vitro. (D) Scanning electron microscopy image of a 3D printed antibiotic scaffold depicting the lattice patterning (80x magnification).