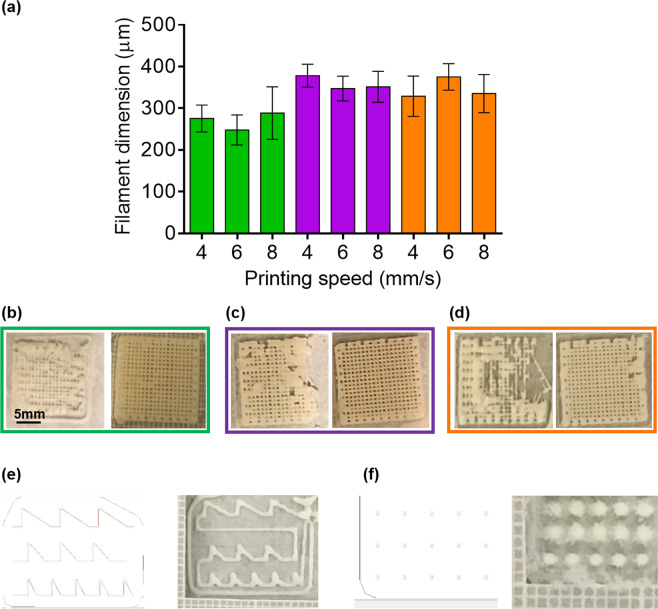

Figure 1.

Scaffold macro-morphological characterisation and resolution assessment. (a) Scaffold filament diameter at different speed and alginate concentration with volume integration: 11% (green), 9% (purple), 7% (orange); (b) Printed scaffolds with 11% of alginate concentration under (left panel) and over (right panel) the minimum speed (6 mm/s). (c) same as (b) for printed scaffolds with 9% of alginate concentration and minimum speed of 10 mm/s. (d) same as (b) for printed scaffolds with 7% of alginate concentration and minimum speed of 14 mm/s. (e) Example of validation tests of printed corners at 60°, 45° and 30°:.STL file (left panel); printed trajectory (right panel). (f) Example of validation tests of printed drops:.STL file (left panel); printed trajectory (right panel). Wilcoxon sign rank test was performed and statistical significance was set at p < 0.05. Data are represented as median ± discrepancy.