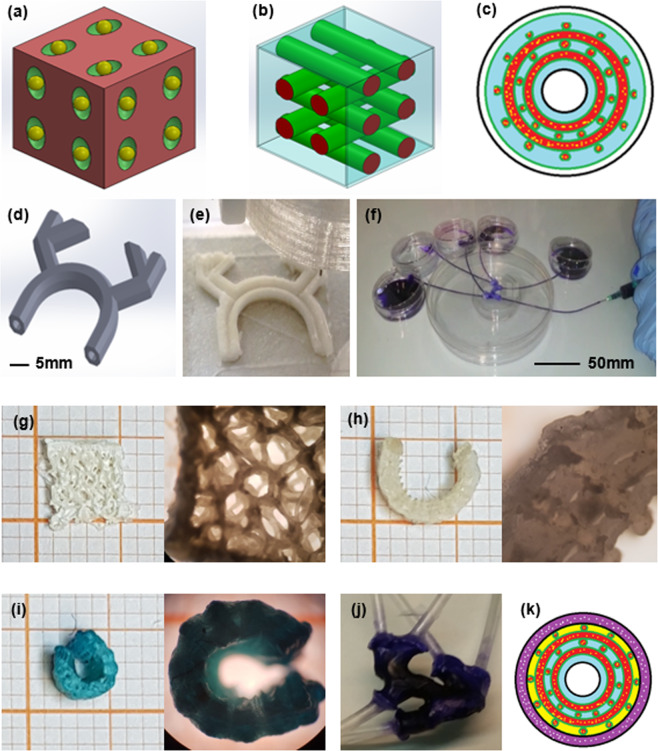

Figure 6.

Bio-composite material vessel fabrication. (a) Composite biomaterial (bio-based, biocompatible and biodegradable): matrix (red, functions), interface (green, performance and stability) and reinforcement (yellow, fibre, nanoparticles, nano-tubes, etc.). (b) Bio-composite material (Nano-functionalised 4D bio-engineered scaffold): matrix (blue, functions), interface (green, performance and stability) and fibre (red, composite/biocomposite scaffold reinforcement).(c) Bio-composite material vessel schema: nano-laden fibre (yellow points and red), interface (green), not functionalised matrix (blue) and functionalised matrix (white). (d) 3D digital model of complex vessel. (e) Complex vessel section; (f) Nano-functionalised 4D Bio-engineered scaffold perfusion test. (g) Complex geometry aerogel scaffold (left panel) and related detail (right panel, 4x magnification). (h) Aerogel with functionalised surface micro-porosity (left panel) and related detail (right panel, 4x magnification). (i) Nano-laden bioengineered scaffold (left panel) and related detail (right panel, 4x magnification). (j) Dehydrated 5D bioprinted vascular device after more than 24 months of petri dish storage. (k) Bio-composite material customisation schema: nano-laden fibre (yellow points and red), interface (green), not functionalised matrix (blue), functionalised matrix for dedicated cells (yellow), adhesive coating (black) and customised matrix for physiology analyses (white point and violet).