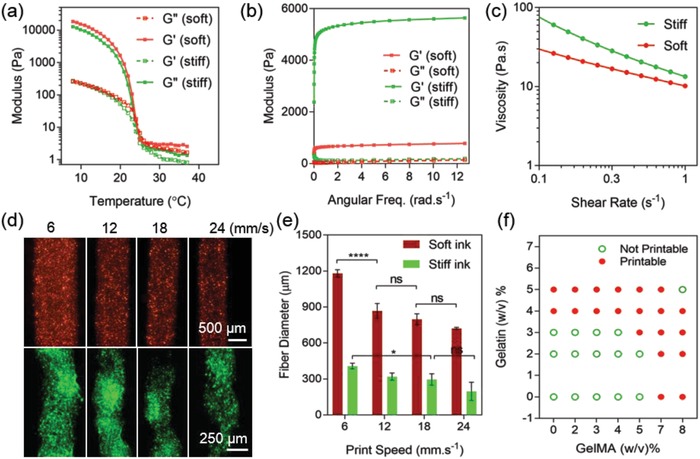

Figure 2.

Rheological properties of the soft and stiff inks. a) Temperature‐dependent behavior of soft and stiff inks affecting the storage (G') and loss (G”) moduli, thus printability of each ink (N = 3). b) Storage (G') and loss (G”) moduli of soft and stiff inks across a frequency sweep (N = 3). c) Change of viscosity with increments of shear stress for both inks showing the shear thinning behavior of the inks (N = 3). d) Fluorescence imaging of dyed extruded fibers using the soft (red) and stiff (green) bioinks across a variation of nozzle printing speeds. The soft ink creates thicker fibers due to lower viscosity. e) Characterization of fiber diameter by nozzle printing speed for the extruded fibers shown in (d). The extruded fiber diameters ranged from 200 to 480 µm for the stiff ink and 550 to 1200 µm for the soft ink with lower viscosity (N = 4). f) Printability of the GelMA and gelatin optimized for printing.