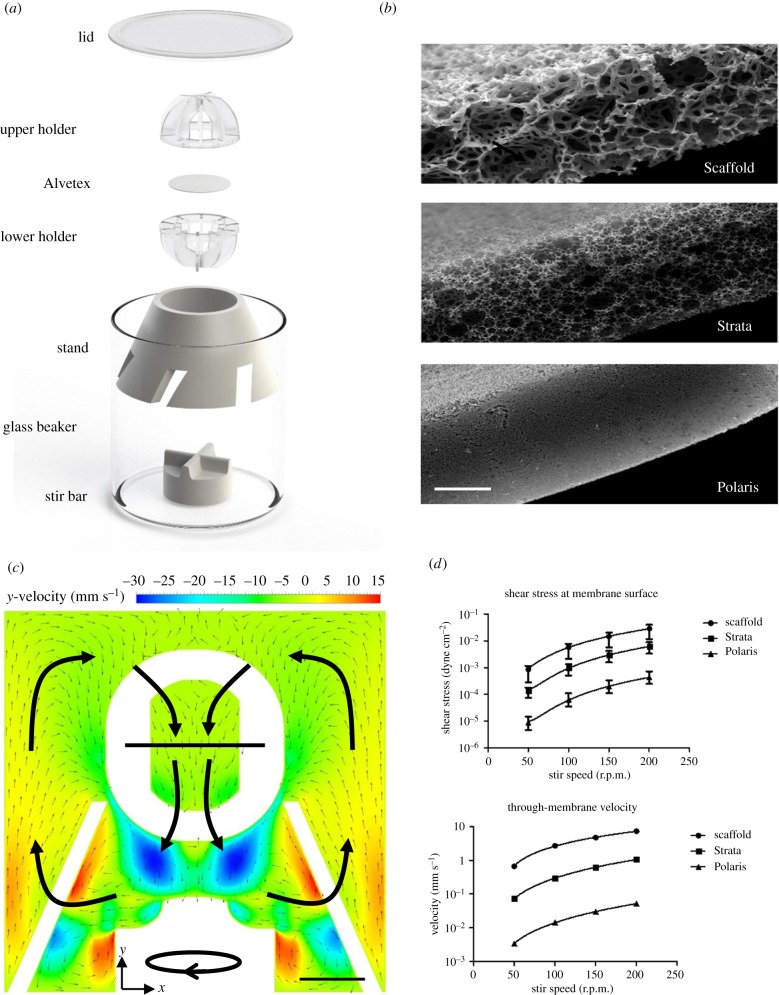

Figure 1.

Schematic, technical details and fluid flow of the bench-top bioreactor. (a) The system is composed of a glass beaker with an inner diameter of 60 mm and height of 70 mm with a volume of 198 ml. In the beaker sits a PTFE stand to secure the holder, into which the Alvetex membrane is placed. The stir bar is placed beneath the PTFE stand in order to generate the fluid flow. The 25 mm stir bar is commercially available (Fisher Scientific), while the rest of the apparatus was custom made by the Durham University mechanical workshops. (b) Scanning electron microscopy images of the three different forms of Alvetex membrane used in this study. Images courtesy of Reprocell Europe. Scale bar is 100 µm. (c) The CFD analysis of the system with an Alvetex Strata membrane inserted and the stirrer at 100 r.p.m. Fluid recirculation in the x–y plane is shown by the vectors, while the y-(vertical-) velocity component is shown by the heat map. Large arrows are added manually to show overall fluid recirculation pattern. Scale bar is 10 mm. (d) Shear stress and through-membrane velocity values were calculated in the system across a range of stir speeds. Values are mass weighted averages with error bars denoting the maximum and minimum values.