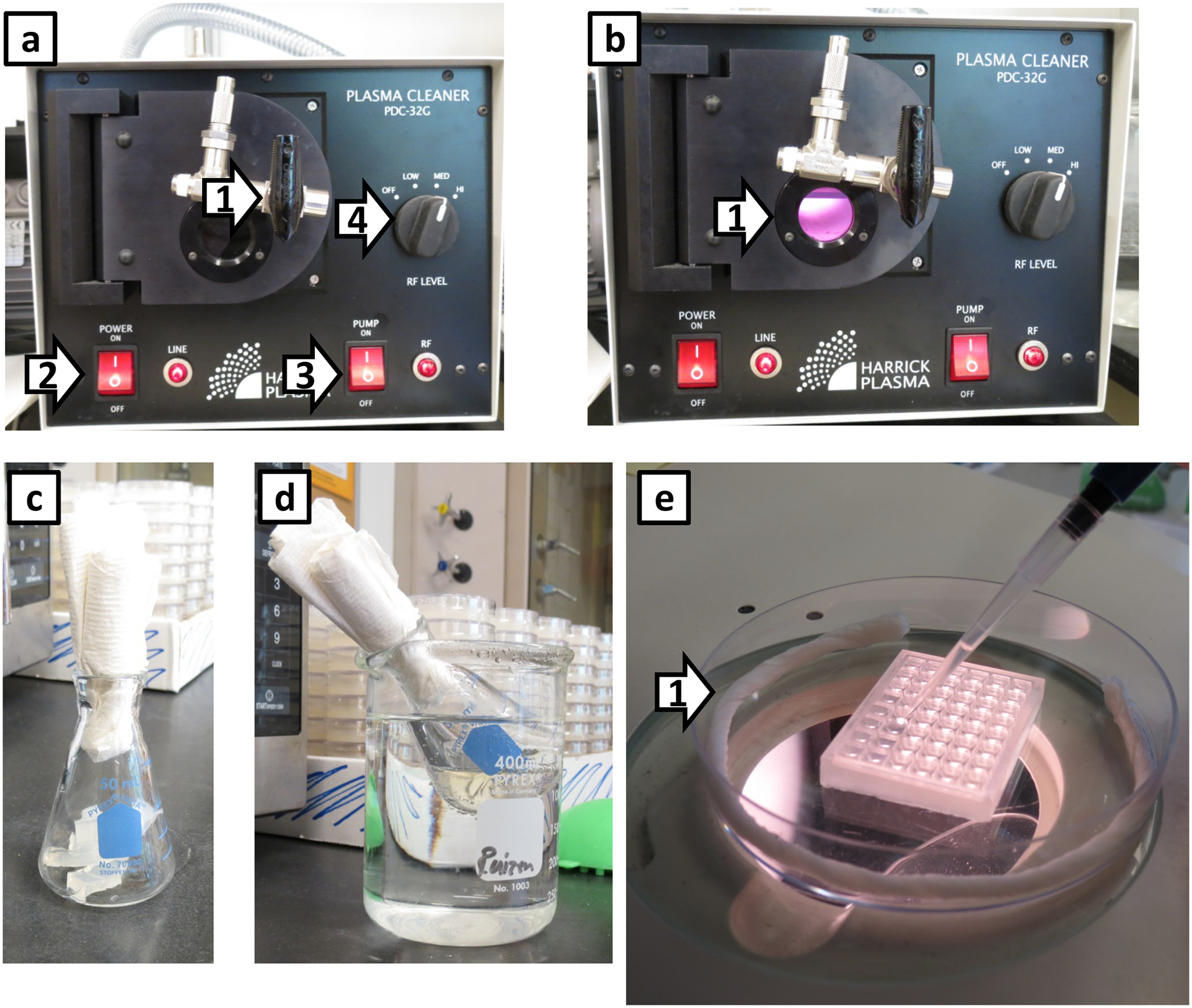

Figure 4. Preparing and filling the WorMotel.

(a) Plasma oxygen cleaner with the vacuum pump turned on before plasma oxygen is formed in the chamber. These are the settings used for plasma oxygen treating the chip. Arrow 1: Valve to control gas into the chamber. Arrow 2: On/Off switch for the plasma cleaner. Arrow 3: On/Off switch for the vacuum pump. The switch on the vacuum pump is always switched to On. Arrow 4: radio frequency (RF) control; we set it on medium. In (b), the reduced pressure produced by the vacuum pump has generated plasma oxygen in the chamber, which has a purple/pink glow (Arrow 1). Running the vacuum pump approximately 10 seconds is sufficient. (c) 50 mL Erlenmeyer flask with ~11.5 mL of solid NGM agar prior to melting. (d) Heated Erlenmeyer flask placed in the beaker of hot water to hold its temperature while filling the WorMotel chip. (e) Filling the WorMotel chip. Arrow 1 indicates a moistened Kimwipe rolled up in the petri dish to prevent the agar from drying out in the WorMotel chip. Depending on the humidity of the lab space, an additional Kimwipe may be required.