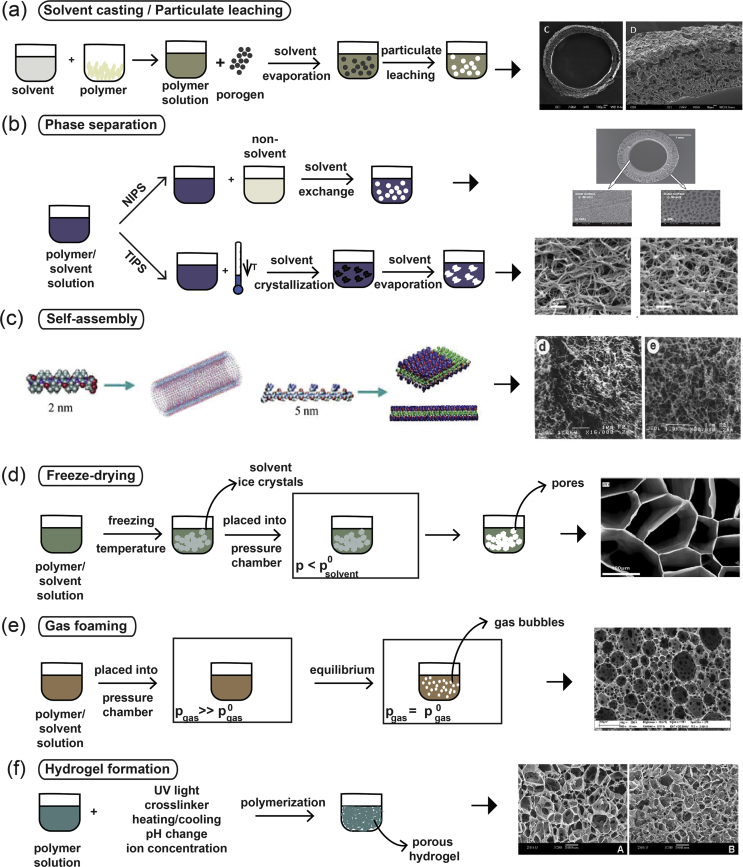

Fig. 2.

(a) Solvent casting/particulate leaching fabrication method. The polymer powder is dissolved in a solvent to create a polymer solution, to which a porogen is added. The polymer hardens through the evaporation of the solvent, and the final network within the scaffold is created by leaching the porogen out of the structure [42]. (b) Phase separation processes depicting the differences between NIPS [43] and TIPS [44]. (c) Example of the structure of a peptide amphiphile that is used in the self-assembly fabrication technique. The chemical structure and the molecular model of peptide amphiphiles are shown [45]. Fabrication processes of (d) freeze-drying [46], (e) gas foaming [47], and (f) hydrogel formation [48]. Scaffold images reprinted with permission from (a) Kokai et al. [42], (b) Oh et al. [43] and Sun et al. [44], (c) Zhao and Zhang [45] and Holmes et al. [49] (Copyright (2000) National Academy of Sciences), (d) Stokols and Tuszynski [46], (e) Barbetta et al. [47], and (f) Zhang et al. [48]. NIPS, non-solvent–induced phase separation; TIPS, thermally induced phase separation.