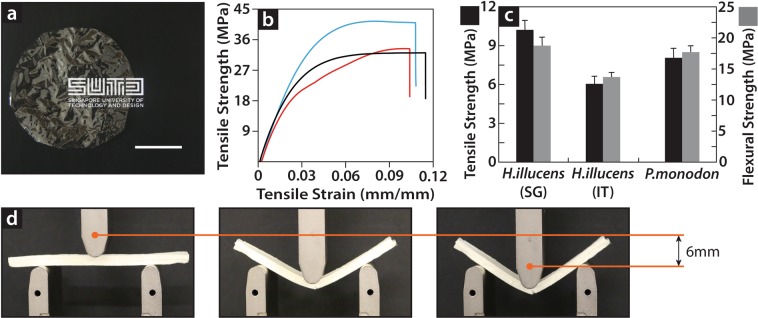

Figure 3.

Mechanical test of bio-converted insect chitosan and chitinous composites. (a) A chitosan film with a diameter of 12 cm and thickness of 200 µm bio-converted from food waste and placed in front a university logo to reflect the film transparency. (b) Mechanical characteristics of chitosan films from bio-converted food waste waste (P. monodon, blue line; Singaporean H. illucens, red line; Italian H. illucens, black line). The obtained results are similar to those previously reported for crustacean shells, highlighting the suitability of this new source to reproduce the manufacturing levels achieved using the latter. (c) Mechanical characteristics of cellulose–chitin composites (FLAMs) prepared using urban refuse are similar to those of the previously reported crustacean-based counterpart. The resulting material exhibits mechanical properties within the range of those of soft-wood, high-density polymeric foams, and high-porosity metal foams. (d) Stages of the three-point bending test of insect FLAM, form the initial stage (left), right after the elastic region (center), and at breaking (right).