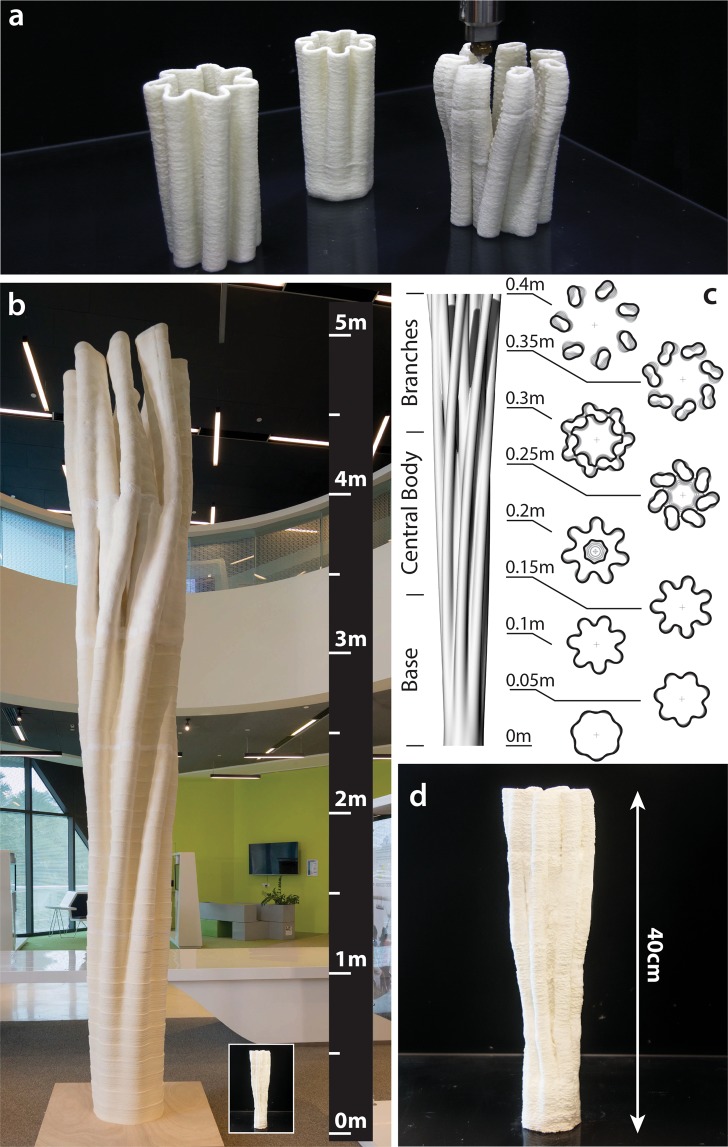

Figure 4.

Additive manufacture with bio-converted chitin and cellulose from urban refuses. (a) Printing of chitin–cellulose composites derived from urban refuse. The object printed is a replica of “the Hydra”, a geometry that cannot be reproduced by casting/molding techniques. The printing process (Supplementary Movie 1) is performed by segmentation, affording three parts that are joined together using FLAM material. (b) Image comparing the original Hydra, which is produced using crustacean chitin and plant cellulose, to the scaled version produced from bio-converted chitin and cellulose from urban waste (inset). The image included four orders of geometrical control from the half-millimeter printing thread used for the scaled version to the 5-m size of the original one. (c) Sketch of the internal geometry defining the hydra. The three segments are marked at the left margin. The right side shows the geometrical cross-section at different heights. The diameter of the base is half of that at the top, rendering an unfavorable inverted funnel structure to the item to highlight the mechanical properties of the material. (d) Photograph of the insect-based replica of the Hydra.