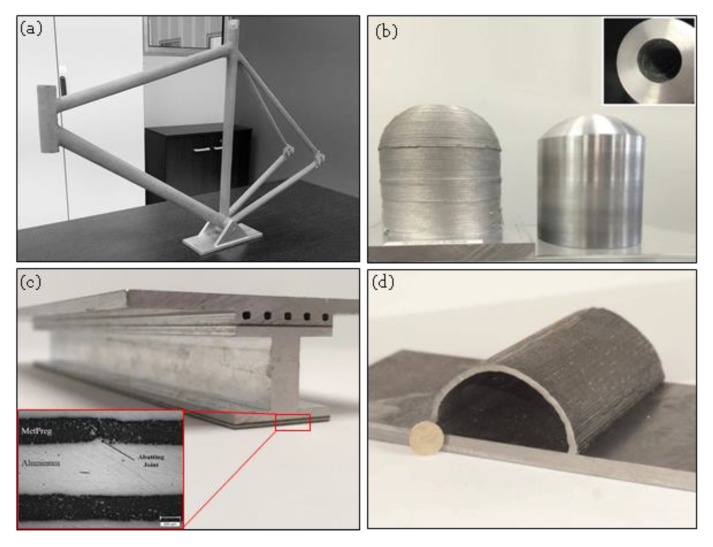

Figure 21.

(a) A single step 3D printed titanium bicycle frame in 25 min using Titomic’s CSAM system (Courtesy of Titomic, Melbourne, Australia), (b) Al6061 hollow dome as fabricated by MELD technology and after finish machining, 115 mm tall, 100 mm diameter part with 25 mm wall thickness, fabrication time: 2 h (Courtesy of Aeroprobe, Christiansburg, VG, USA), (c) MMC laminates (MetPreg) composed of continuous alumina fibers and a matrix of pure aluminum are selectively layered for selective reinforcement of the rib structure (Courtesy of Fabrisonic, Columbus, OH, USA), (d) 50 mm radius semicircle printed using WAAM [163].