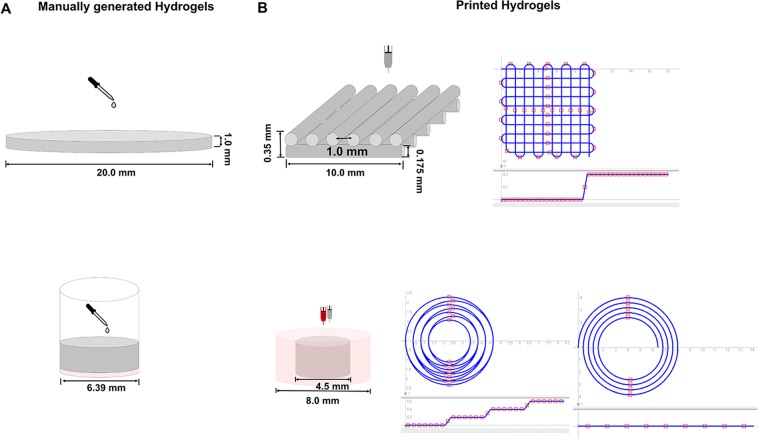

Figure 2.

Graphical illustration of manually generated and printed 3D scaffolds. (A) Top: Graphical illustration of manual generation of cell-free hydrogels for rheological characterization of storage and loss modulus and gravimetric determination of swellability: The bioink formulations were pipetted into flat cylindrical molds, covered using quartz glass, and cured using 365 nm. Bottom: Graphical illustration of manual generation of the 2-phase hydrogels: Cell-free bone bioink was pipetted into 96-well plate wells (red) and covered with vascularization bioink including HDMECs and ASCs (grey). (B) Top: Graphical illustration of printed hydrogels: Cell-free two-layered grid structure for the evaluation of the inks’ printability and trajectory patterns for printing the two-layer grid structure. Bottom: Graphical illustration of printed concentrical co-culture constructs consisting of cell-loaded or cell-free bone bioink (outer part, red) and cell-loaded or cell-free vascularization bioink (inner part, grey) and trajectory patterns for printing the concentric cylinders. (Partly reproduced from49).