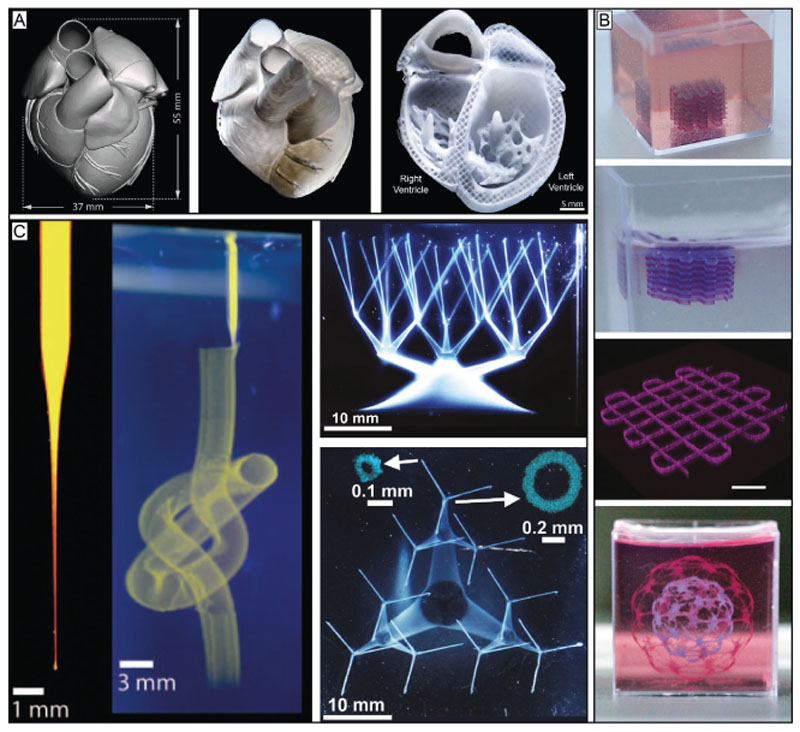

Figure 6.

Support bath printing allows to print suspended structures and overhangs, and provides structural stability when using low viscosity bioinks, enhancing control over shape and resolution. A) Based on a CAD-model a construct from collagen I, a material that is usually not printable by itself, was printed using the support bath approach. The support bath, based on gelatin, allowed the deposition of a low viscous collagen ink, utilizing an in situ crosslinking approach, and fabrication of complex structures with high shape fidelity that closely resemble the CAD file templates. Reproduced with permission.[53] Copyright 2019, AAAS. B) The method can also be used to generate filigree multimaterial constructs which could not be printed with classical extrusion-based bioprinting. The alginate-based support bath was enzymatically degraded to gently harvest the fragile objects. Reproduced under the terms of the Creative Commons CC-BY 4.0 License (https://creativecommons.org/licenses/by/4.0/).[88] Copyright 2019, The Authors, Published by Wiley-VCH. C) Carbopol as bath material in combination with a very thin nozzle (50 μm tip) enabled printing of structures with high resolution and challenging shapes. Reproduced with permission.[168] Copyright 2015, The Authors, published by AAAS. Reproduced/modified from ref. [16]. © 2016, The Authors, some rights reserved; exclusive licensee American Association for the Advancement of Science. Distributed under a Creative Commons Attribution NonCommercial License 4.0 (CC BY-NC).