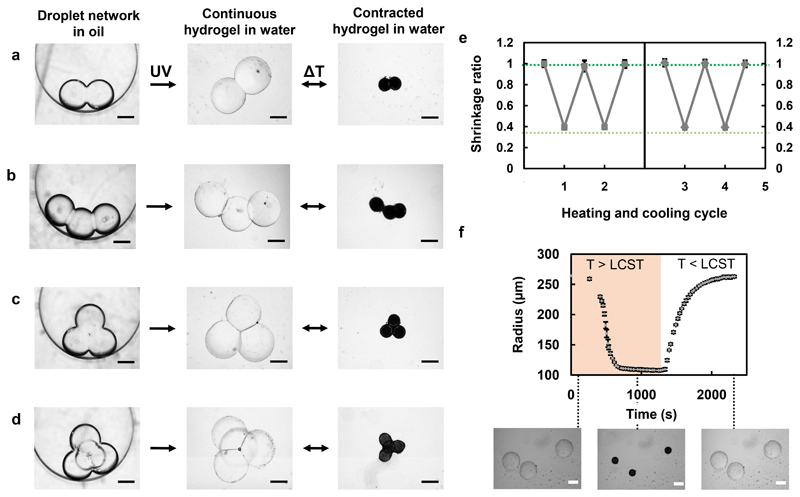

Figure 2. Formation and temperature response of PNIPAm hydrogel structures templated with droplet networks.

a, Brightfield images of a NIPAm pre-gel-containing droplet pair in oil. After UV photopolymerization, a continuous hydrogel structure was formed. The structure was transferred into water and reversible isotropic contraction occurred at 42°C, above the LCST of PNIPAm. b-d, A three-droplet chain (b), three-droplet triangle (c) and four-droplet pyramid (d) were also fabricated and reversibly contracted at 42°C. Structures appear black upon heating above the LCST, due to an increase in the refractive index of PNIPAm. e, Four cycles of heating and cooling were performed for the droplet pair-, chain- and triangle-templated structures. The radii of droplets comprising these structures were measured at 25°C and 42°C, and normalised to their initial radii. The resulting mean shrinkage ratios are shown for each temperature across the cycles. The break in the x axis indicates that two cycles were performed on the structures on two different days. The dark green dotted line delineates the fully swollen structure, whereas the pale green dotted line delineates the fully contracted structure. f, Radii of 3 individual, non-connected PNIPAm droplets measured during contraction, while heating to 42°C, and reswelling, while cooling to room temperature. Error bars in (e) and (f) represent one standard deviation about the mean shrinkage ratio or the radius, respectively. Scale bars correspond to 250 μm.