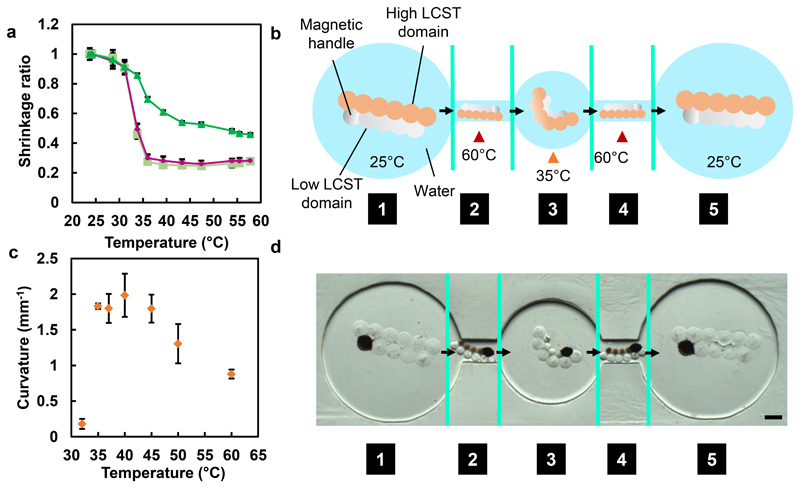

Figure 6. A magnetically- and dual temperature-responsive shape-changing structure.

a, Temperature dependence of the shrinkage ratio of PNIPAm hydrogel droplets (pale green squares), or droplets containing in addition 1 mM (pink circles) or 3 mM PEGDAAm (dark green triangles). Error bars indicate one standard deviation about the mean shrinkage ratio. b, Design of the multi-responsive shape-changing structure. The low LCST domain contained 0.4 mM PEGDAAm, while the high LCST domain contained 3.5 mM PEGDAAm. A magnetic handle in the low LCST domain contained MagneHis™ Ni-Particles. Initially, the hydrogel structure is trapped in chamber (1). After heating to 60°C, both domains of the structure contract and it can be pulled through a narrow channel by a magnetic field (2). Once in the central chamber, it is cooled to 35°C and becomes curled as the low LCST domain contracts (3). When heated once more to 60°C, it again contracts and can be magnetically pulled through a channel (4) into the final chamber. Here, the hydrogel is cooled to room temperature and returns to its original size and shape (5). Green lines indicate where the temperature has been changed. (c) Temperature dependence of the curvature of the fabricated multi-responsive shape-changing structure. Error bars indicate one standard deviation about the mean curvature of three structures. (d) Brightfield images of the dual-controlled shape-changing structure at positions (1)-(5). Green lines indicate the change in temperature, as well as where images are stitched together. Scale bar corresponds to 500 μm. See Supplementary Figure 10 for uncropped individual images.