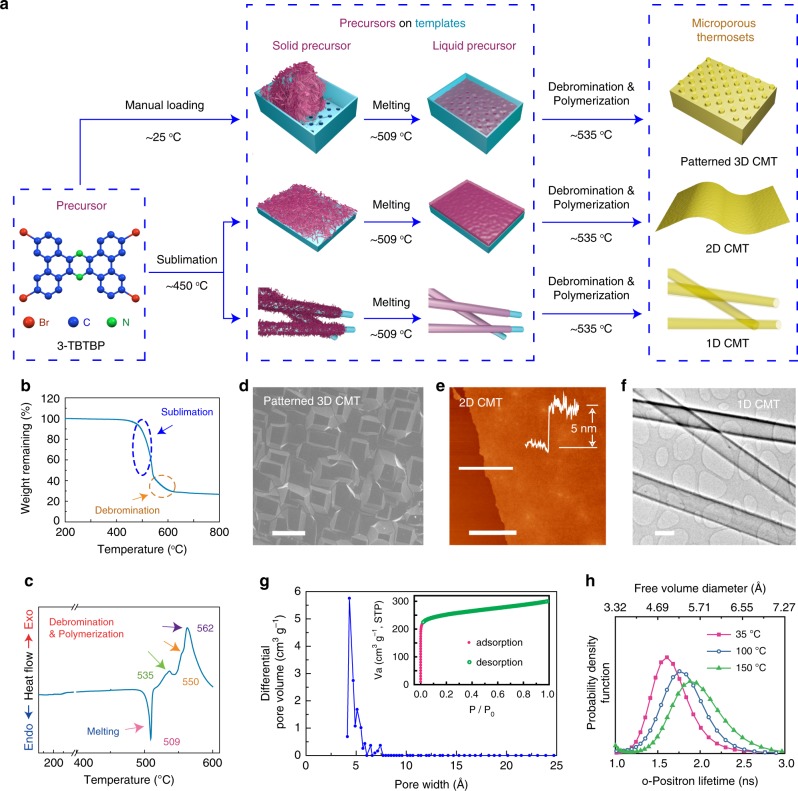

Fig. 1. Synthesis and characterization of conjugated microporous thermoset.

a Schematic illustration of the thermosetting process to make 3D, 2D, and 1D CMT, depending upon the substrate (a holder with patterned bottom plate for patterned 3D CMT; Silicon wafer for 2D CMT; Cu nanowires for 1D CMT). b Thermal gravimetric analysis of 3-TBTBP. c Differential scanning calorimetry curve of 3-TBTBP. d SEM image showing the surface of a patterned 3D CMT. e AFM topography image of ~5-nm-thick CMT film on Si wafer; Insert: corresponding height profile. f TEM image of 1D CMT nanotubes. g Pore size distribution derived based on Ar adsorption data; Inset: Ar isotherm profile of the CMT measured at 86 K. h The o-positron lifetime (and hence free volume diameter) distribution in CMT at 35 °C, 100 °C, and 150 °C based on PALS measurements. The scale bars are 20 μm, 3 μm, and 200 nm for d, e, and f, respectively.