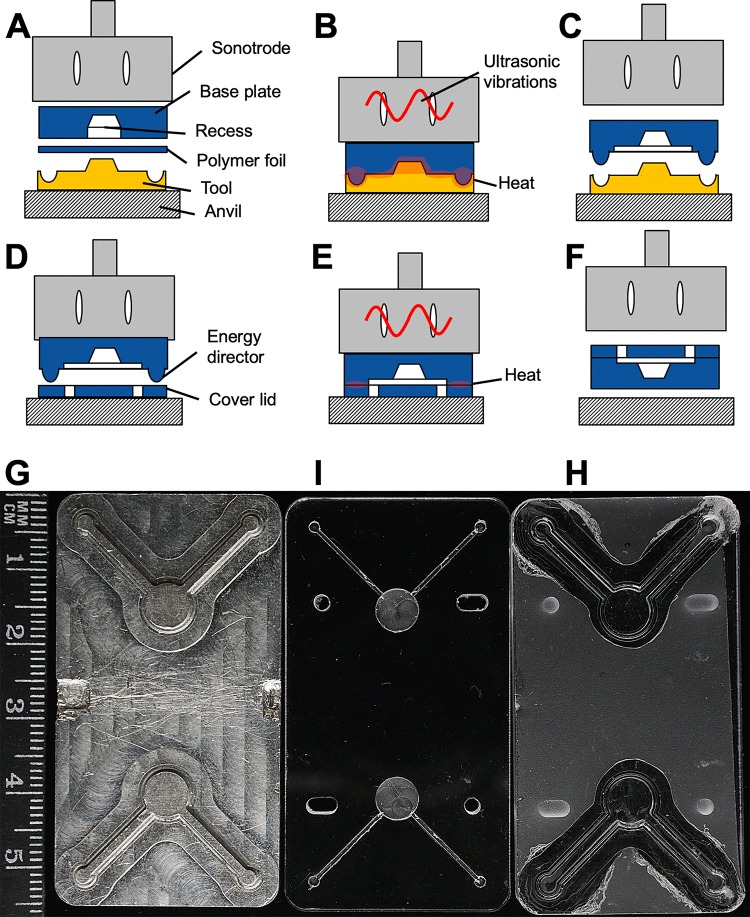

Fig 1. Fabrication of a microchip by ultrasonic hot embossing and welding.

A, Polymer plate and foil are placed between tool and sonotrode; B, The sonotrode presses the polymer layers onto the tool and generates friction heat, the polymer layers are welded together to form a micro patterned chip base; C, After cooling down and solidifying, the chip base is removed from the tool; D, The micro patterned plate and a polymer lid are placed onto the anvil; E, The sonotrode welds both parts by friction heat; F, The sealed microfluidic chip is removed from the machine; G, Aluminum replica tool for two microfluidic chambers fabricated by micro milling; I, Polymer base plate with machined recesses for excess molten polymer; H, Ultrasonically hot embossed chip with cover lid.