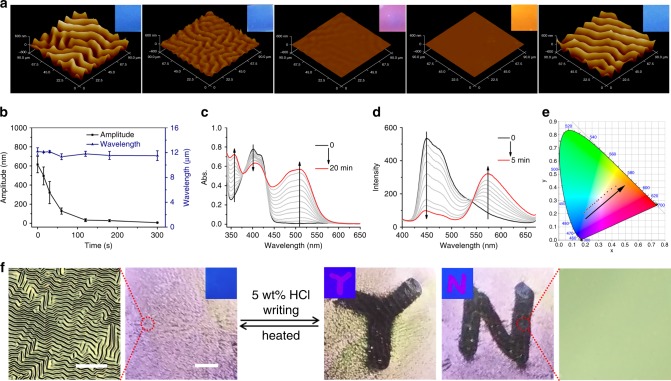

Fig. 4. Evolution process of the dual-pattern on HCl vapor treatment.

a 3D AFM images of wrinkles when the wrinkled samples were exposed to 56.4 ppm HCl vapor for 0, 60, 180, and 300 s, and subsequently reheated to release the HCl. Inset pictures are corresponding photographs of PDMS taken under UV light. b Amplitude (A, black square, left vertical axis) and wavelength (λ, blue triangle, right vertical axis) of the wrinkles as a function of 56.4 ppm HCl vapor treatment time. Error bars represent the standard deviations of three independent data. Source data are provided as a Source Data file. c UV–vis spectra of P4VP-nBA-S/DSP-OH film for different times of 56.4 ppm HCl vapor treatment. d Fluorescence emission spectra of P4VP-nBA-S/DSP-OH film for different times of 56.4 ppm HCl vapor treatment. e The fluorescence color of P4VP-nBA-S/DSP-OH film at different HCl vapor treatment times illustrated in the CIE color space. f Photographs of letters “Y” and “N” on PDMS under UV light and natural light written by a writing brush with 5 wt% HCl. Scale bar: 2 mm. The corresponding LSCM images exhibiting characteristic wrinkled and flat surface. Scale bar: 100 μm.