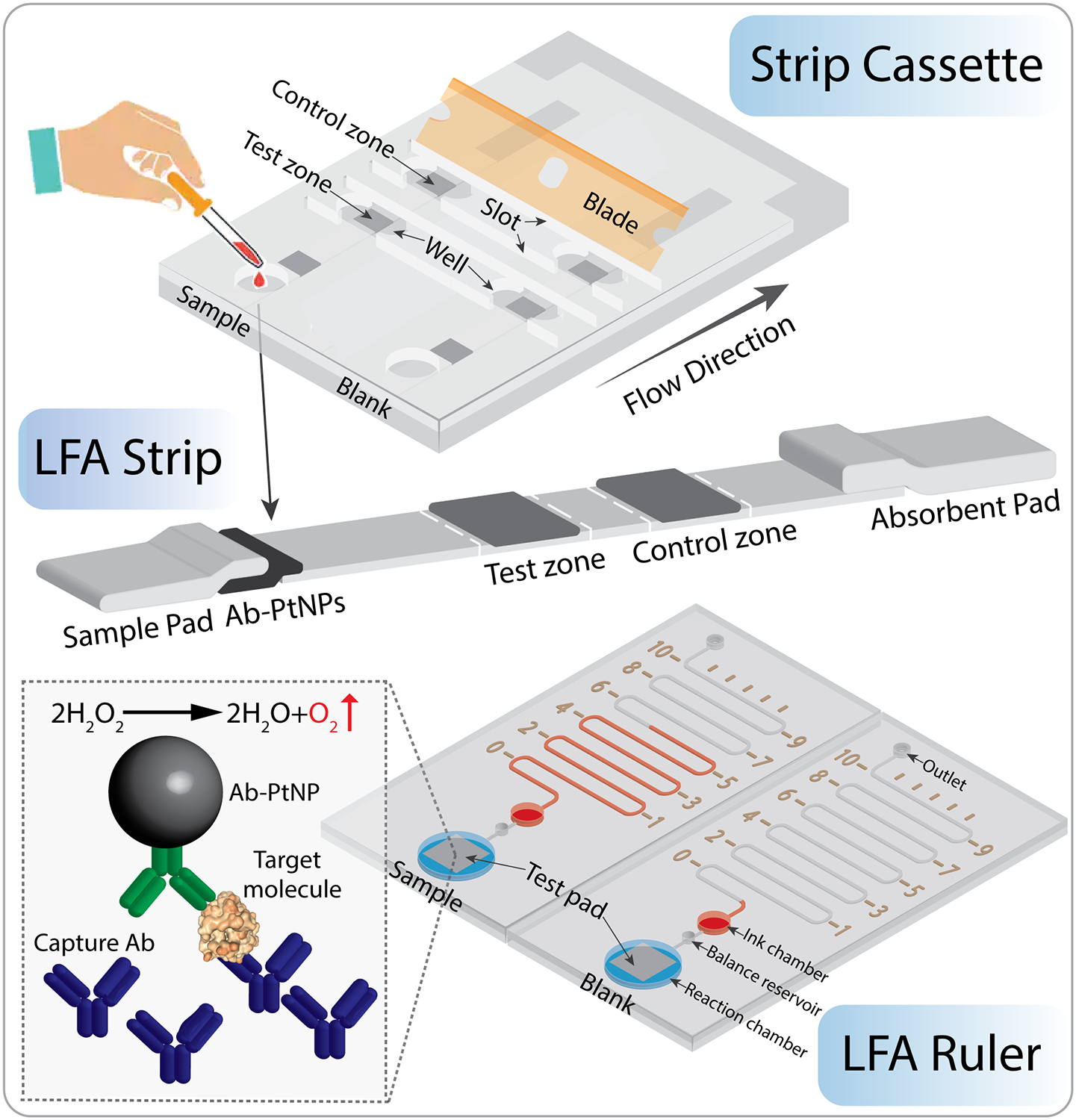

Figure 1.

Working principle of the strip cassette and LFA ruler. First, LFA strips were placed into the strip cassette, and sample or blank control was loaded into sample chambers. After LFA completion (~15 min), a blade was inserted into the slots to cut the test zone of LFA strips. Then the pads were added from the well of strip cassette to the reaction chamber in the LFA ruler. The LFA ruler contains microchannel, distance markers, ink chamber, balance reservoir, reaction chamber, outlet and sealing tapes. The PtNPs captured in the test zone pad catalyze the breakdown of H2O2 into water and oxygen, which pushes the red ink forward in the microchannel. The ink advancement distance is proportional to the amount of target molecules in the sample. The LFA ruler achieves quantitative detection of biomarkers by the naked eye. Not to scale.