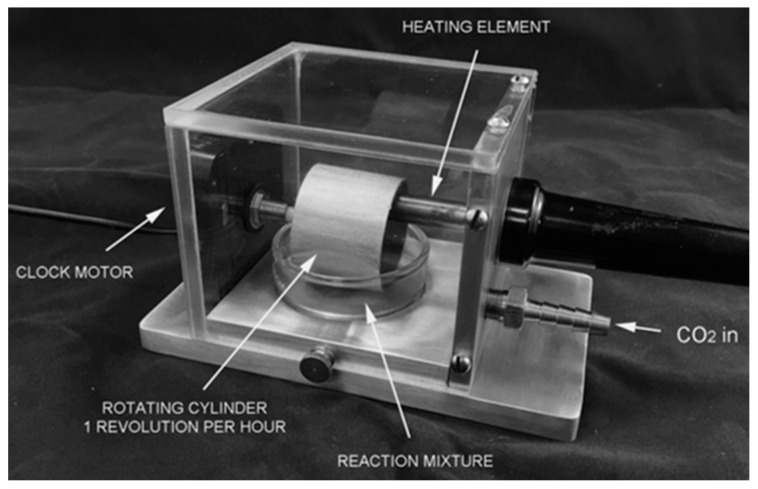

Figure A1.

An early wet–dry cycling apparatus prototype developed by Prof. David Deamer to promote monomer polymerization. This apparatus consists of a hollow stainless-steel cylinder, which rotates once per hour via the minute hand of a clock motor. The lower portion of the cylinder rotates into a reaction mixture placed into the dish below. A heating element is used to heat the cylinder to 80°C. CO2 or N2 enters the apparatus at a low rate (<5 ccs/s) to carry off the water produced by the condensation reactions that polymerize mononucleotides. A typical reaction mixture holds 10 mM mononucleotides in their acid form, together with either 10 mM phospholipid or 100 mM ammonium chloride, both of which promote polymerization. As the cylinder rotates out of the reaction mixture, a thin film of the mixture is picked up on the burnished surface of the cylinder and would be quickly dried by the heat so that the monomers could polymerize. The dried film then re-dissolves when the cylinder rotates back into the mixture. To prevent the entire 15 mL from evaporating, a perfusion pump delivers water at the same rate it evaporated.