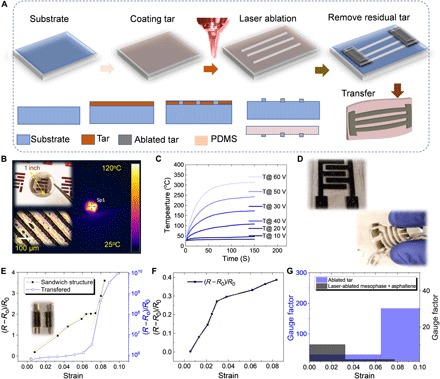

Fig. 5. Applications of laser-treated tar in electronics and additive manufacturing.

(A) Fabrication schematics of laser-printed devices, including patterning, washing, and transfer process. (B) Laser-printed tar-based devices including a transparent heater, an interdigit supercapacitor, and a flexible strain sensor transferred onto PDMS. Details of performance are shown in the Supplementary Materials. (C) Heating responses under different bias. Temperature will plateau after ~20 s, and the saturated temperature increases with input bias voltage. Heating temperature can reach up to 300°C under 60-V bias. (D) Optical image of laser-printed supercapacitor and strain sensor. (E) Performance of strain sensor made of laser-ablated tar. (F) Performance of strain sensor made of laser-ablated MP-asphaltene composite. (G) Comparison of gauge factors of strain sensor in (E) and (F). Photo credit: Xining Zang, Massachusetts Institute of Technology.