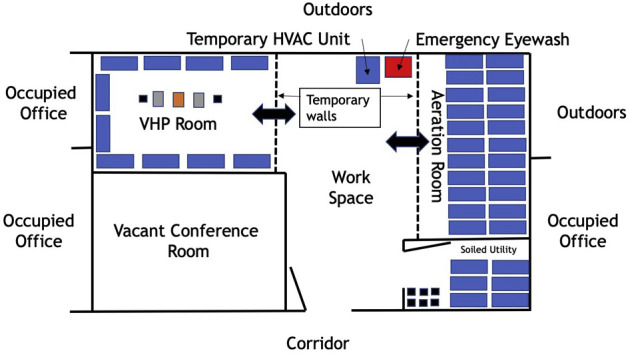

Figure 4.

Schematic of the vaporized hydrogen peroxide (VHP) room, which includes 5 different areas: the vacant conference room is where the VHP associates work in between cycles. The soiled utility room is where the soiled collection bins are placed on the wire racks. The wire racks are then rolled into the VHP room, where each Tyvek pouch holding one N95 respirator is removed from the soiled collection bin and placed on shelves in a flat position. Next, the disinfection process occurs in the VHP room. The Bioquell Z-2, 2 Bioquell aeration units, and a fan sit in the center of the VHP room. The aeration, or off-gassing, room is where N95 respirators aerate until the H2O2 sensor reads 0 parts per million, both in the room and at the level of the Tyvek pouches. The workspace includes a temporary heating ventilation and air conditioning system (HVAC) unit since the central HVAC capabilities were sealed off, hand hygiene stations, and an emergency eyewash station.