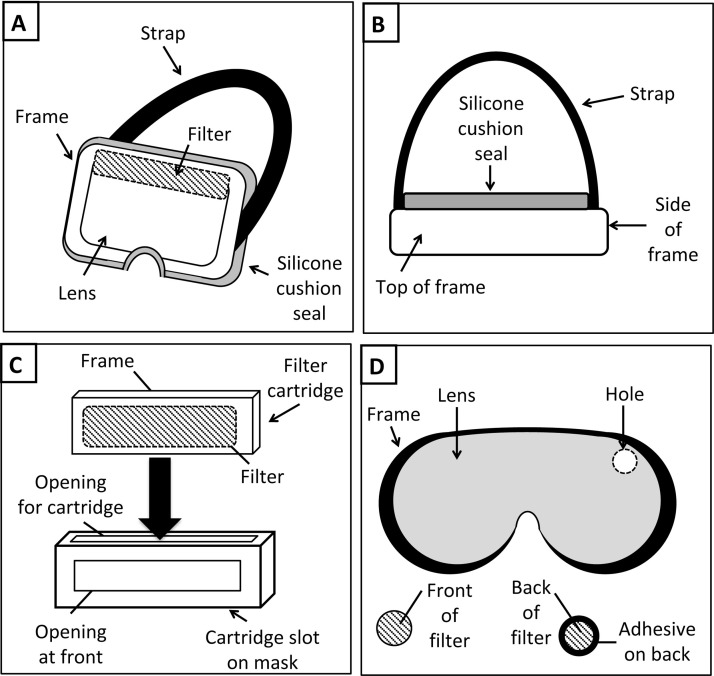

Fig. 4.

Illustration of various design considerations for a filtered eye mask (FEM). Figure 4A illustrates a front-oblique view of an FEM design with a large, high-efficiency filter on the top portion of the lens of the mask. The top position of the filter could potentially help to more efficiently eliminate water vapor. An air-filled silicone tube is utilized to create an air-tight silicone cushion seal with the user's face. Figure 4B illustrates a top-down view of the design in Figure 4A. Note that the frame creates a separation between the face and the lens, which is designed to fit over prescription glasses. Figure 4C illustrates a front view of a filter cartridge with a frame and filter. The filter cartridge is placed (large arrow) into the cartridge slot on an FEM. Note that there is an opening at the top where the filter cartridge is slid in and an opening at the front for ventilation, wherein the air mass in front of the eyes remains clean and virus-free. An air-tight design of the cartridge is important to prevent any non-filtered air from entering into the FEM. Figure 4D illustrates an alternative design, wherein the FEM has a hole on the front of the lens. This hole can be covered with a small replaceable filter with an adhesive portion to secure it to the lens. Additional filters could be implemented, so as to improve virus-free air flow through the mask. Note that the FEM is meant to be worn in conjunction with a separate respiratory mask during times at which a user is exposed, such as working in the intensive care unit on active COVID-19 patients. After high-risk exposure is finished, the filter can be discarded and the goggles washed. The goggles can be reused with a fresh filter placed prior to a subsequent exposure.