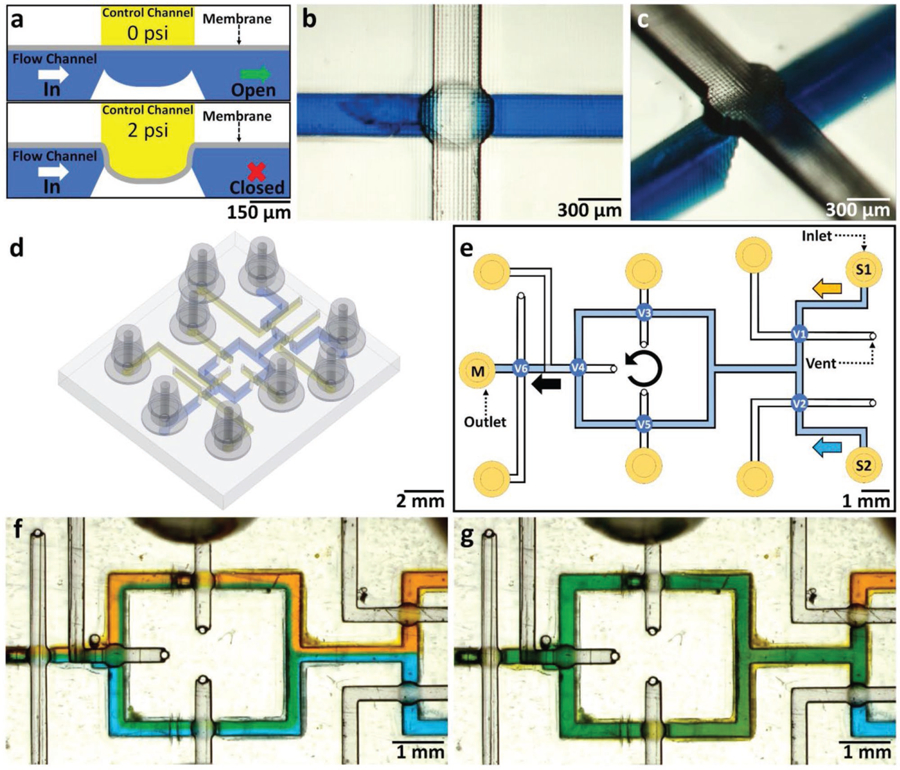

Figure 6.

Active microfluidic devices—microvalves and rotary mixer. a) Cross-sectional schematic of a single 3D-printed 500 µm diameter circular “pinch” valve. The valve consists of two orthogonal channels (the flow channel and a control channel) separated by a thin (20 µm thick) membrane. The valve is closed by applying a pneumatic pressure of 2 psi to the membrane via the control channel, pressing the membrane on the valve seat, thus closing the flow channel below. b) CAD design of the circular pinch valve, showing the flow channel (blue) and control channel (yellow). c) Oblique-view micrograph of a single 3D-printed circular pinch valve at the intersection of a 300 µm wide flow channel (filled with blue dye) and a 300 µm wide control channel (transparent). d) Oblique view of CAD design of rotary mixer. e) Top-view CAD design of rotary mixer channel layout with six individually actuated valves (V1–V6). Yellow (S1) and blue (S2) dyes are flown with V6 closed at 7 psi. V3–V5 are sequentially opened and closed at 3 psi to mix fluids in a counterclockwise motion. V6 is opened to flow mixed fluid to the outlet (M1). f) Magnified top-view micrograph of the rotary mixer device, showing the laminar flow of the two dyes as they are initially flown with V6 closed at 7 psi. g) Magnified top-view micrograph of the rotary mixer device after 1.5 min of mixing, showing green dye flowing to the outlet (M1).