Abstract

The objective of this study was to investigate the sound absorption coefficient of bark-based insulation panels made of softwood barks Spruce (Picea abies (L.) H. Karst.) and Larch (Larix decidua Mill.) by means of impedance tube, with a frequency range between 125 and 4000 Hz. The highest efficiency of sound absorption was recorded for spruce bark-based insulation boards bonded with urea-formaldehyde resin, at a level of 1000 and 2000 Hz. The potential of noise reduction of larch bark-based panels glued with tannin-based adhesive covers the same frequency interval. The experimental results show that softwood bark, an underrated material, can substitute expensive materials that involve more grey energy in sound insulation applications. Compared with wood-based composites, the engineered spruce bark (with coarse-grained and fine-grained particles) can absorb the sound even better than MDF, particleboard or OSB. Therefore, the sound absorption coefficient values strengthen the application of insulation panels based on tree bark as structural elements for the noise reduction in residential buildings, and concurrently they open the new ways for a deeper research in this field.

Keywords: spruce and larch bark, sound absorption coefficient, impedance tube, biomass, up-cycling

1. Introduction

Noise control is an important issue in modern life. A lot of factors contribute to its increase, e.g., population growth, expansion of the urban centers, densification of the housing sector, correlated to the number of vehicles, the development of automatic machines in industrial companies and devices [1,2,3,4].

Noise pollution is the second most important environmental factor in Europe, North America and South-East Asia, contributing to different diseases after air pollution. People of all age groups are becoming more vulnerable to mental stress, heart diseases, sleep disturbance, tinnitus, learning disabilities etc. [5,6,7]. The range of frequencies for the human voice and musical sound is mostly from 125 to 3000 Hz [8,9]. The human audible frequency range extends up to 15 kHz for most persons, and can reach 20 kHz for children and young people [10]. The sound absorption coefficient gives information about the acoustical effectiveness of a material and is defined as the fraction of the energy of incident sound waves absorbed by the material [1,4]. The values of the sound absorption coefficient are between 0 (no absorption) and 1 (complete absorption, e.g., acoustical walls in recording studios) [11,12,13]. Sound insulation (expressed as the transmission loss factor) and absorption are two different properties. Materials that are effective as sound insulators are mostly not useful as sound absorbers and vice versa. Parameters that influence values of these sound insulation and absorption include density, porosity and material thickness. Thicker, denser, and heavier material have higher transmission loss factor values, and porous materials are more effective at sound absorption [14,15,16,17].

Noise control in buildings is ensured through insulation from external sound sources and absorption of sound generated within a space by blocking the transmission of sound from a room to another [18].

Non-woven materials have been analyzed as sound absorption materials by various researchers who studied cotton [19], cellulose [20] and needle [21]. Rwawiire et al. [22] investigated the sound insulation characteristics of non-woven fabric from the inner bark of three Ficus species. The measurements revealed that the sound absorption of the bark cloths have higher sound absorption properties at higher frequencies, with an improved absorption coefficient when increasing the bark cloth fiber layers [22]. The planks of birch bark were used for a hundred years as sound absorbers under turf roofs in Sweden, serving also as waterproof membrane [23]. Natural materials such as bark, jute, flax, kenaf, hemp, coir fiber, wood, wool, coconut, straw, cane and corn husk can be designed as thermal and sound absorbers with the advantage of availability [24,25,26,27], sustainability [28,29,30,31,32,33,34,35] and biodegrability [36,37,38,39,40,41,42].

This paper presents some aspects about sound absorption properties of tree bark insulation panels made of larch (Larix decidua Mill.) and spruce (Picea abies (L.) H.Karst.), with different particle sizes. The sound absorption coefficient of these panels was compared with wood-based composites from a previous research conducted by Smardzewski et al. [9]. This is an example of the upcycling application of woody biomass as resource for sound and thermal insulation boards that can diminish the noise level in a building. In the context of the scarcity of raw materials, the cascading use of wood and forest residues plays an important role, and should be weighed as a basic concept within the circular economy [43,44]. Bio-economy can be considered environmentally beneficial only if the bio-based resources are managed sustainably [45].

2. Materials and Methods

The spruce and larch bark were collected in a local sawmill in Salzburg County, Austria. The bark planks were ground by means of a 4-shaft shredder RS40 at Untha Co. (Kuchl, Austria), with a mesh of 30 mm. Subsequently, the bark particles were dried at 60 °C and 200 to 250 mbar in a vacuum kiln dryer Brunner-Hildebrand High VAC-S, HV-S1 from 65% to 9.0% moisture content.

The material was repeatedly screened according to EN 15149-1:2011 [46] with a sieve shaker Retsch AS 200, to obtain particles in a size spectrum of 8–13 mm and 10–30 mm.

Four types of bark-based insulation boards were manufactured (Table 1). The spruce bark was bonded with 10% urea formaldehyde type Prefere 10F102 (MetaDynea Austria, Krems, Austria). The larck bark from Graggaber sawmill, Unternberg, Austria was glued with 10% tannin-based adhesive. The formulation included Mimosa tannin extract powder (Acacia mearnsii) from Phenotan, Tanac, Brasil, hexa-methylenetetramine (hexamine) from Merck Schuchardt, Hohenbrunn, Germany (C99 %) and sodium hydroxide solution (C32 %) from Carl Roth, Karlsruhe, Germany. A total of 50% tannin extract powder and 50% water were stirred with a mechanical mixer at 700 and 1500 rpm. A total of 10% of hexamine was added and sodium hydroxide was used to adjust the pH value to 9. The boards were pressed at 180 °C for five minutes with a press factor of 24 s/mm [47,48].

Table 1.

Particle size, dimensions, density levels and adhesive type of the bark insulation boards.

| Board Type | Bark Particle Size (mm) | Board Thickness (mm) | Boards Dimension (mm) | Board Density (kg/m³) | Adhesive |

|---|---|---|---|---|---|

| Spruce fine | 8–13 | 21 | 500 × 500 | 500 | 10% UF |

| Spruce coarse | 10–30 | 20 | 500 × 500 | 414 | 10% UF |

| Larch coarse, thin | 10–30 | 11 | 500 × 500 | 690 | 10% tannin |

| Larch coarse, thick | 10–30 | 19 | 500 × 500 | 571 | 10% tannin |

100 mm diameter samples were cut from bark-based insulation boards manufactured in the laboratories of Salzburg University of Applied Sciences. The thermal conductivity, mechanical properties, microstructures and volatile organic compounds (VOC) emissions of these panels were analyzed in publications by Kain et al. [48,49,50,51,52].

The samples were prepared from different areas of the boards and cut according to EN 326- 1:1994 [53] and ISO16999 [54]. The average moisture content of the samples was 8–9%, according to EN 322:2005 [55].

Acoustical Measurements in Impedance Tube

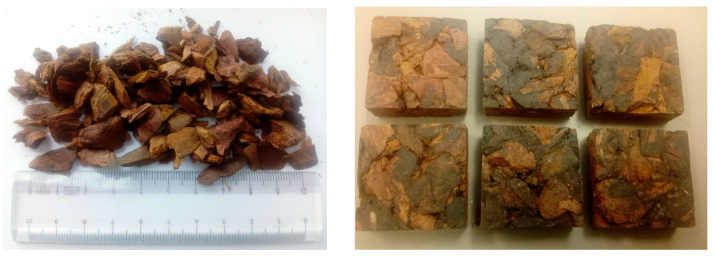

The acoustical properties of bark-based insulation panels (Figure 1) were measured with an impedance tube system at Krämer & Stegmaier, Berlin, Germany, according to EN ISO 10534-2:2001 (transfer function method) [56]. The system consists of two different sized pipes, which are optimized for high and low frequencies. This covers a frequency range from 50 to 5000 Hz. In contrast to measurements in the reverberation chamber, only small material samples are required for the impedance tube (30 or 150 mm edge length) [57].

Figure 1.

Larch bark particles (8–13 mm) (left) and bark based composite specimens (right) for acoustic measurements.

The test specimen was introduced in a stationary acoustic field generated by a speaker under normal incidence. The absorption coefficient and the impedance were determined using the transfer function between two microphones. By evaluating the incident and reflected sound energy, the sound absorption capacity of the material was determined [58]. The precision of results depends on the design specifications of the impedance tube. These are the diameter of the tube, the distance of the microphones from the samples and the distance between the microphones [59].

The share of sound absorbed by the bark-based insulation samples was calculated using Equations (1) and (2):

| (1) |

| (2) |

where

α is he sound absorption coefficient

and are intensities of incident and reflected waves

and are the pressures of incident and reflected waves

is the standing wave ratio (the ratio of the maximum to minimum pressure of the sound wave) [60] cited by [61].

3. Results and Discussion

The measurements were carried out with and without wall clearance. The assessments with wall clearance are relevant for products such as multi-layered acoustic panels with cavities.

The acoustical properties of materials can be determined by means of impedance tube. In order to calculate the sound absorption capacity of the larch bark samples, a sound wave was emitted in the direction of the test specimen; and then the reflected sound energy was determined.

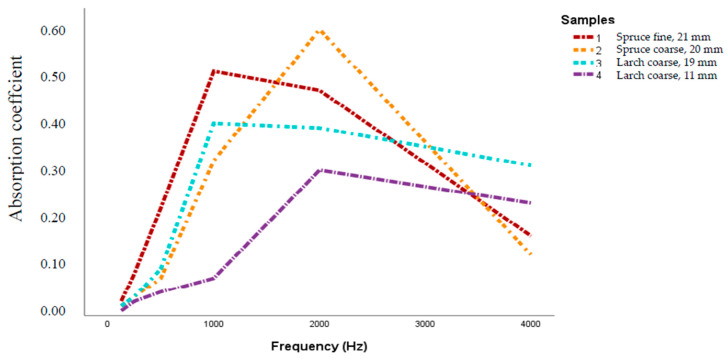

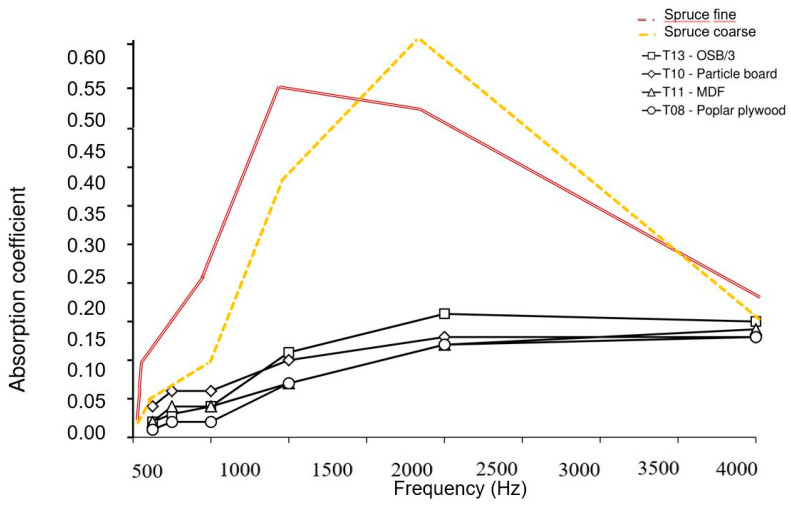

Figure 2 shows how much sound was absorbed by the individual samples at a frequency ranging from 125 to 4000 Hz, without wall clearance.

Figure 2.

Sound absorption coefficient for spruce and larch bark insulation boards, measured without wall clearance.

The thickness of the board plays an important role for the sound absorption coefficient (α), considering here the samples with 19, 20 and 21 mm, compared with the one with 11 mm. The contribution of bark insulation boards to a better sound absorption can be observed in the frequency range of 1000–2000 Hz [9,42,62] when α increases significantly and has a peak at 2000 Hz, at α = 0.61 for the 21 mm sample of spruce board at a density level of 414 kg/m³, compared to α = 0.31 for the 11 mm larch bark sample with a density of 693 kg/m³. Two other peaks were recorded at 1000 Hz for the spruce bark board (α = 0.52) made with fine particles (500 kg/m³) and for the larch bark thick board (α = 0.41) with coarse particles (571 kg/m³). After 2000 Hz α decreases for all testing specimens, meaning that the boards are able to absorb noise at a level of absorption coefficient smaller than 0.62. This experiment shows that the sound absorbing properties of bark based insulating materials can be enhanced by reducing density and increasing thickness. These results are in compliance with Arenas and Crocker [16] and McMullan [17]. Based on these studies, materials that possess a high value of sound absorption are usually porous materials. Sound absorption behavior observed for low-density particleboard showed that this board had higher porosity compared to medium-density particleboard.

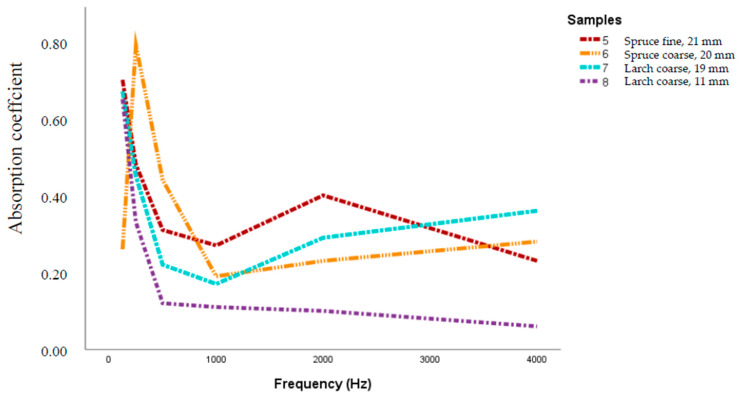

In case of using wall clearance (Figure 3), the sound absorption effect is high at low frequencies, ranging from 125 Hz (very close values, from 0.65 to 0.7). The peak is reached by the 20 mm thick sample made of spruce, with a level of α = 0.79 at 250 Hz. After this frequency, the absorption coefficient decreases abrupt until 1000 Hz, with a short increment up to 0.44 for spruce bark sample with fine-grained particle size (8–13 mm). After that α ranges from 0.36 to 0.06 at 4000 Hz. The lowest value means almost no sound absorption.

Figure 3.

Sound absorption coefficient for spruce and larch bark insulation boards, measured with wall clearance.

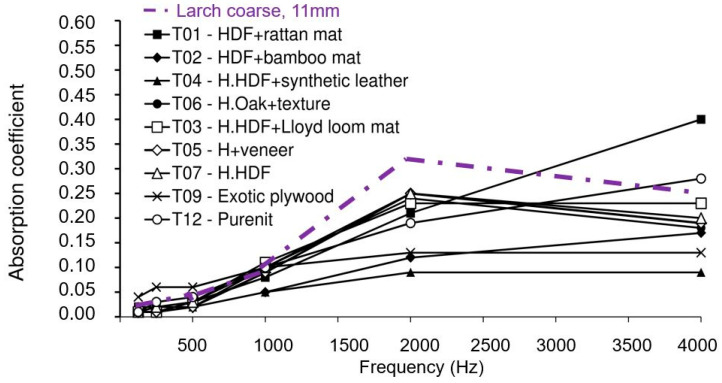

Smardzewski et al. [9] analyzed the sound absorption of 17 different wood-based materials. For a thickness of 7.9 < x < 11 mm, the highest absorption coefficients were recorded between 1000 Hz and 2000 Hz for honeycomb (T07, for a 10 mm thickness: α = 0.10 (1000 Hz), α = 0.25 (2000 Hz)), honeycomb + veneer (T05, for a 9.8 mm thickness: α = 0.09 (1000 Hz), α = 0.25 (2000 Hz)), honeycomb + oak + texture (T06, for a 10.5 thickness: α = 0.10 (1000 Hz), α = 0.24 (2000 Hz)) and honeycomb + Lloyd loom mat (T03, for a 10.2 mm thickness: α = 0.11 (1000 Hz), α = 0.23 (2000 Hz)), compared to α = 0.08 and α = 0.31 at 1000, respectively 2000 Hz for the 11 mm larch bark board, that performed better for this interval of frequencies (Figure 4).

Figure 4.

Dependence of the sound absorption coefficient on frequency for wood-based composites with a thickness 7.9 < x < 11 mm (after Smardzewski et al. [9]).

In the case of medium thicknesses (16 < x < 18.4mm), the wood-based materials with densities from 481 kg/m³ (T10, particleboard), 515 kg/m³ (T08, poplar plywood), 558 kg/m³ (T11, medium density fibreboard, MDF) and 613 kg/m³ (T13, oriented strand board) did not reach sound absorption coefficients higher than 0.15 (Figure 5). The spruce bark samples with similar density levels (414 kg/m³ for spruce coarse and 500 kg/m³ for spruce fine) can absorb sound better at frequencies between 250 and 4000 Hz, with two peaks at 0.52 (spuce fine, at 1000 Hz) and 0.61 (spruce coarse, at 2000 Hz).

Figure 5.

Dependence of the sound absorption coefficient on frequency for wood-based composites with a thickness 16 < x < 18.4 mm and a density 500 < y < 600 kg/m³ (after Smardzewski et al. [9]).

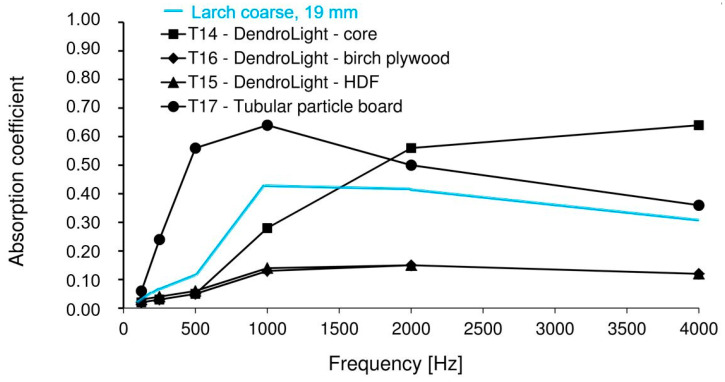

For thickness interval 22.3 < x < 28 mm, the wood-based materials with densities that raged from 220 kg/m³ (T17, tubular particle board), 270 kg/m³ (T14, DendroLight—core), 459 kg/m³ (T15, DendroLight—planked with HDF) and 493 kg/m³ (T16, DendroLight—planked with birch plywood) performed better to the larch bark board with a thickness of 19.3 mm (Figure 5). The best values of α coefficient (0.06, 0.24, 0.56, 0.64, 0.5 and 0.36) were recorded for the T17 panels, with the best acoustic absorbability for all frequencies for the interval between 125 and 4000 Hz. At 1 kHz the 19 mm larch bark panel recorded an α coefficient with 35% smaller than the T17 tubular particleboard, and at 2 KHz was 20% reduced, but these results are consistent with the data shown in Figure 6. These outputs correspond with experimental data of Karlinasari et al. [63], Yang et al. [64], Zulkifli et al. [65,66] and Smardzewski et al. [67], where the maximum sound absorption coefficient was achieved by wood and wood composites at middle frequencies (about 1500–3000 Hz). These results are also in compliance to authors [9,14,68,69,70], in that the best sound absorption capabilities of wood based composites were achieved by the samples with low density of surface layers and high porosity.

Figure 6.

Dependence of the sound absorption coefficient on frequency for wood-based composites with a thickness 22.3 < x < 28 mm and a density 220 < y < 500 kg/m³ (after Smardzewski et al. [9]).

The human ear is most sensitive to noise at central frequencies [71], therefore bark-based insulation panels can be recommended as sound insulation applications.

4. Conclusions

This paper reveals that the sound insulation properties of the tested larch and spruce bark panels open a new subject related to the advantages of the use of wood biomass. The thickness of the board plays an important role for the sound absorption coefficient.

The sound absorption coefficient for the panel with a thickness of 19 mm were compared with wood-based composites with similar thicknesses and it was found that the spruce bark panels (with coarse and fine particles) can absorb sound even better than OSB, particleboard, MDF and poplar plywood, therefore the values of the sound absorption coefficient confine their application as structural elements for reducing the noise effects in residential buildings, and open new ways for a deeper research in this field.

The spruce composite panels with densities lower than 500 kg/m³ are able to attenuate up to 60% more sound, compared to densified larch agglomerated boards (600, respectively 700 kg/m³).

In case of using a clearance wall (Figure 3), the sound absorption effect is high (0.7 for the panels with spruce with fine-grained particles and with larch bark) at low frequencies, starting from 125 Hz. These findings encourage further investigations about sound insulation properties of the bark-based insulation panels.

This research brings an expanding knowledge in the area of composites based on softwood bark and emphasizes on the advantages of an underrated material, namely tree bark, that can substitute wood and other materials that involve more grey energy that affect their life cycle assessment.

Acknowledgments

We would like to express our special thanks to Jerzy Smardzewski for his support with the diagrams of experimental data from reference [9]. Many thanks to Graggaber Co. in Unternberg for providing the bark, Untha Co. in Kuchl for size reduction of bark and to MetaDynea Co., Krems, Austria for providing the adhesives. Many thanks to Krämer & Co., Berlin, Germany, for the measurements of sound absorption coefficient in impedance tube.

Author Contributions

Funding acquisition and data analysis, A.D. and E.M.T.; experiment design, G.K. and A.D.; investigation, A.D.; resources: A.D., G.K., M.C.B.; supervision, R.R.; writing and proofreading, E.M.T., M.C.B., and Ľ.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the Slovak Research and Development Agency under contracts no. APVV-17-0583 and APVV-18-0378, and VEGA 1/0717/19.

Conflicts of Interest

The authors declare no conflict of interest

References

- 1.Bohatkiewicz J. Noise Control Plans in Cities–Selected Issues and Necessary Changes in Approach to Measures and Methods of Protectin. Transp. Res. Procedia. 2016;14:2744–2753. doi: 10.1016/j.trpro.2016.05.458. [DOI] [Google Scholar]

- 2.Murphy E., King E.A. Strategic environmental noise mapping: Methodological issues concerning the implementation of the EU Environmental Noise Directive and their policy implications. Environ. Int. 2010;36:290–298. doi: 10.1016/j.envint.2009.11.006. [DOI] [PubMed] [Google Scholar]

- 3.Godshall W., Davis J. Acoustical Absorption Properties of Wood-Based Panel Materials. USDA Forest Service; Madison, WI, USA: 1969. [Google Scholar]

- 4.Casas-Ledón Y., Salgado K.D., Cea J., Arteaga-Pérez L.E., Fuentealba C. Life cycle assessment of innovative insulation panels based on eucalyptus bark fibers. J. Clean. Prod. 2020;249:119356. doi: 10.1016/j.jclepro.2019.119356. [DOI] [Google Scholar]

- 5.Moszynski P. Who warns noise pollution is a gowing harard health in Europe. BMJ. 2011;342:d2114. doi: 10.1136/bmj.d2114. [DOI] [PubMed] [Google Scholar]

- 6.Oudin A. Short review: Air pollution, noise and lack of greenness as risk factors for Alzheimer’s disease–epidemiologic and experimental evidence. Neurochem. Int. 2020;134:104646. doi: 10.1016/j.neuint.2019.104646. [DOI] [PubMed] [Google Scholar]

- 7.Klompmaker J.O., Janssen N.A., Bloemsma L.D., Gehring U., Wijga A.H., Brink C.V.D., Lebret E., Brunekreef B., Hoek G. Residential surrounding green, air pollution, traffic noise and self-perceived general health. Environ. Res. 2019;179:108751. doi: 10.1016/j.envres.2019.108751. [DOI] [PubMed] [Google Scholar]

- 8.Pépiot E. Male and female speech: A study of mean f0, f0 range, phonation type and speech rate in Parisian French and American English speakers. [(accessed on 23 February 2020)];Speech Prosody. 2014 7:305–309. Available online: https://halshs.archives-ouvertes.fr/halshs-00999332. [Google Scholar]

- 9.Smardzewski J., Kamisiński T., Dziurka D., Mirski R., Majewski A., Flach A., Pilch A. Sound absorption of wood-based materials. Holzforschung. 2015;69:431–439. doi: 10.1515/hf-2014-0114. [DOI] [Google Scholar]

- 10.Hornsby B., Ricketts T. The effects of hearing loss on the contribution of high- and low-frequency speech information to speech understanding. II. Sloping hearing loss. J. Acoust. Soc. Am. 2006;119:1752–1763. doi: 10.1121/1.2161432. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 11.Peng L. Advanced High Strength Natural Fibre Composites in Construction. Woodhead Publishing; Cambridge, UK: 2017. Sound absorption and insulation functional composites; pp. 333–373. [Google Scholar]

- 12.Tsalagkas D., Börcsök Z., Pásztory Z. Thermal, physical and mechanical properties of surface overlaid bark-based insulation panels. Eur. J. Wood Prod. 2019;77:721–730. doi: 10.1007/s00107-019-01436-5. [DOI] [Google Scholar]

- 13.Pásztory Z., Börcsök Z., Tsalagkas D. IOP Conference Series: Earth and Environmental Science, Proceedings of the 5th International Conference on Environment and Renewable Energy, Ho Chi Minh City, Vietnam, 25–28 February 2019. Volume 307 IOP Publishing Ltd.; Bristol, UK: 2019. Density optimization for the manufacturing of bark-based thermal insulation panels. [Google Scholar]

- 14.Karlinasari L., Hermawan D., Maddu A., Martianto B., Lucky I.K., Nugroho N., Hadi Y.S. Acosutical properties of particleboards made from betung bamboo as building construction material. Bioresources. 2012;7:5700–5709. doi: 10.15376/biores.7.4.5700-5709. [DOI] [Google Scholar]

- 15.Bucur V. Acoustic of Wood. 2nd ed. Springer; Berling/Heidelberg, Germany: 2006. pp. 7–36. [Google Scholar]

- 16.Arenas J., Crocker M.J. Recent trends in porous sound-absorbing materials. Sound Vib. 2010;44:12–18. [Google Scholar]

- 17.McMullan R. Environmental Science in Building. 5th ed. Palgrave; New York, NY, USA: 2002. pp. 200–251. [Google Scholar]

- 18.Mehta M., Johnson J., Rocafort J. Architectural Acoustics Principles and Design. Pearson; London, UK: 1999. pp. 301–306. [Google Scholar]

- 19.Jiang N., Chen J.Y., Parikh D.V. Acoustical evaluation of carbonized and activated cotton nonwovens. Bioresour. Technol. 2009;100:6533–6536. doi: 10.1016/j.biortech.2008.10.062. [DOI] [PubMed] [Google Scholar]

- 20.Krucińska I., Gliścińska E., Michalak M., Ciechańska D., Kazimierczak J., Bloda A. Sound-absorbing green composites based on cellulose ultrashort/ultra-fine fibers. Text Res. J. 2014;85:646–657. doi: 10.1177/0040517514553873. [DOI] [Google Scholar]

- 21.Shahani F., Soltani P., Zarrebini M. The analysis of acoustic characteristics and sound absorption coefficient of needle punched nonwoven fabrics. J. Eng. Fibers Fabr. 2014;9:84–92. doi: 10.1177/155892501400900210. [DOI] [Google Scholar]

- 22.Rwawiire S., Tomkova B., Gliscinska E., Krucinska I., Michalak M., Militky J., Jabbar A. Investigation of sound absorption properties of bark cloth nonwoven fabric and composites. Autex Res. J. 2015;15:173–180. doi: 10.1515/aut-2015-0010. [DOI] [Google Scholar]

- 23.Berge B. The Ecology of Building Materials. 2nd ed. Elsevier; Oxford, UK: 2001. p. 427. [Google Scholar]

- 24.Cao L., Fua Q., Yang S., Dinga B., Yu J. Porous materials for sound absorption. Compos. Commun. 2018;10:25–35. doi: 10.1016/j.coco.2018.05.001. [DOI] [Google Scholar]

- 25.Barbu M.C., Reh R., Çavdar A.D. Non-Wood Lignocellulosic Composites. Materials Science and Engineering: Concepts, Methodologies, Tools, and Applications. IGI Global; Hershey, PA, USA: 2017. [DOI] [Google Scholar]

- 26.Réh R., Igaz R., Krišťák Ľ., Ružiak I., Gajtanska M., Božíková M., Kučerka M. Functionality of Beech Bark in Adhesive Mixtures Used in Plywood and Its Effect on the Stability Associated with Material Systems. Materials. 2019;12:1298. doi: 10.3390/ma12081298. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 27.Hassan T., Jamshaid H., Mishra R., Khan M.Q., Petru M., Novak J., Choteborsky R., Hromasova M. Acoustic, Mechanical and Thermal Properties of Green Composites Reinforced with Natural Fibers Waste. Polymers. 2020;12:654. doi: 10.3390/polym12030654. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 28.Danihelová A., Němec M., Gergel T., Gejdoš M., Gordanová J., Sčensný P. Usage of recycled technical textiles as thermal insulation and an acoustic absorber. Sustainability. 2019;11:2968. doi: 10.3390/su11102968. [DOI] [Google Scholar]

- 29.Němec M., Igaz R., Gergel T., Danihelová A., Ondrejka V., Krišťák L., Gejdoš M., Kminiak R. Acoustic and thermophysical properties of insulation materials based on wood wool. Akustika. 2019;33:115–123. [Google Scholar]

- 30.Tudor E.M., Barbu M.C., Petutschnigg A., Réh R., Krišťák Ľ. Analysis of Larch-Bark Capacity for Formaldehyde Removal in Wood Adhesives. Int. J. Environ. Res. Public Health. 2020;17:764. doi: 10.3390/ijerph17030764. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 31.Bekhta P., Sedliačik J. Environmentally-Friendly High-Density Polyethylene-Bonded Plywood Panels. Polymers. 2019;11:1166. doi: 10.3390/polym11071166. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 32.Balali A., Hakimelahi A., Valipour A. Identification and prioritization of passive energy consumption optimization measures in the building industry: An Iranian case study. J. Build. Eng. 2020;30:101239. doi: 10.1016/j.jobe.2020.101239. [DOI] [Google Scholar]

- 33.Grazieschi G., Gori P., Lombardi L., Asdrubali F. Life cycle energy minimization of autonomous buildings. J. Build. Eng. 2020;30:101229. doi: 10.1016/j.jobe.2020.101229. [DOI] [Google Scholar]

- 34.Koezjakov A., Urge-Vorsatz D., Crijns-Graus W., van den Broek M. The relationship between operational energy demand and embodied energy in Dutch residential buildings. Energy Build. 2018;165:233–245. doi: 10.1016/j.enbuild.2018.01.036. [DOI] [Google Scholar]

- 35.Lorincová S., Hitka M., Štarchoň P., Stachová K. Strategic Instrument for Sustainability of Human Resource Management in Small and Medium-Sized Enterprises Using Management Data. Sustainability. 2018;10:3687. doi: 10.3390/su10103687. [DOI] [Google Scholar]

- 36.Jing W. Ph.D. Thesis. Tongji University; Shanghai, China: 2005. Life-Cycle Assessment of Envelope Structure of Typical Residential Buildings in Cities and Towns in Severe Cold Areas. [Google Scholar]

- 37.Brás A., Gomes V. LCA implementation in the selection of thermal enhanced mortars for energetic rehabilitation of school buildings. Energy Build. 2015;92:1–9. doi: 10.1016/j.enbuild.2015.01.007. [DOI] [Google Scholar]

- 38.Yang Q., Kong L., Tong H., Wang X. Evaluation Model of Environmental Impacts of Insulation Building Envelopes. Sustainability. 2020;12:2258. doi: 10.3390/su12062258. [DOI] [Google Scholar]

- 39.Silvestre J.D., Pargana N., De Brito J., Pinheiro M.D., Durão V. Insulation Cork Boards—Environmental Life Cycle Assessment of an Organic Construction Material. Materials. 2016;9:394. doi: 10.3390/ma9050394. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 40.Nowoświat A., Dulak L. Impact of Cement Dust Pollution on the Surface of Sound-Absorbing Panels on Their Acoustic Properties. Materials. 2020;13:1422. doi: 10.3390/ma13061422. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 41.Hýsek Š., Neuberger P., Sikora A., Schönfelder O., Ditommaso G. Waste Utilization: Insulation Panel from Recycled Polyurethane Particles and Wheat Husks. Materials. 2019;12:3075. doi: 10.3390/ma12193075. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 42.Stanciu M., Curtu I., Cosereanu C., Vasile O., Olarescu C. Evaluation of Absorption Coefficient of Biodegradable Composite Materials with Textile Inserts. Rom. J. Acoust. Vib. 2011;2:99–102. [Google Scholar]

- 43.Tong X., Wang T., Chen Y., Wang Y. Towards an inclusive circular economy: Quantifying the spatial flows of e-waste through the informal sector in China. Resour. Conserv. Recycl. 2018;135:163–171. doi: 10.1016/j.resconrec.2017.10.039. [DOI] [Google Scholar]

- 44.Fan Y., Lee C., Lim J., Klemeš J. Cross-disciplinary approaches towards smart, resilient and sustainable circular economy. J. Clean. Prod. 2019;232:1482–1491. doi: 10.1016/j.jclepro.2019.05.266. [DOI] [Google Scholar]

- 45.Anastasiades K., Blom J., Buyle M., Audenaerta A. Translating the circular economy to bridge construction: Lessons learnt from a critical literature review. Renew. Sustain. Energy Rev. 2020;117:1–11. doi: 10.1016/j.rser.2019.109522. [DOI] [Google Scholar]

- 46.EN 15149-1:2011 Solid Biofuels-Determination of Particle size Distribution—Part 1: Oscillat-ing Screen Method Using Sieve Apertures of 1 mm and Above, -Test Method. CEN, European Committee for Standardization; Brussels, Belgium: 2011. [Google Scholar]

- 47.Tudor E., Barbu M., Petutschnigg A., Réh R. Added-value for wood bark as a coating layer for flooring tiles. J. Clean. Prod. 2017;180:1354–1360. doi: 10.1016/j.jclepro.2017.09.156. [DOI] [Google Scholar]

- 48.Kain G., Lienbacher B., Barbu M., Senck S., Petutschnigg A. Water vapour diffusion resistance of larch (Larix decidua) bark insulation panels and application considerations based on numeric modelling. Constr. Build. Mater. 2018;164:308–316. doi: 10.1016/j.conbuildmat.2017.12.212. [DOI] [Google Scholar]

- 49.Kain G., Lienbacher G., Barbu M.C., Richter K., Petutschnigg A. Larch (Larix decidua) bark insulation board: Interactions of particle orientation, physical-mechanical and thermal properties. Eur. J. Wood Wood Prod. 2018;76:489–498. doi: 10.1007/s00107-017-1271-y. [DOI] [Google Scholar]

- 50.Kain G., Barbu M.C., Richter K., Plank B., Tondi G., Petutschnigg A. Use of tree bark as insulation material. For. Prod. J. 2015;65:S16–S25. [Google Scholar]

- 51.Kain G., Stratev D., Tudor E., Lienbacher B., Weigl M., Barbu M.C., Petutschnigg A. Qualitative investigation on VOC-emissions from spruce (Picea abies) and larch (Larix decidua) loose bark and bark panels. Eur. J. Wood Wood Prod. 2020;78:403–412. doi: 10.1007/s00107-020-01511-2. [DOI] [Google Scholar]

- 52.Kain G., Charwat-Pessler J., Barbu M.C., Plank B., Richter K., Petutschnigg A. Analyzing wood bark insulation board structure using X-ray computed tomography and modeling its thermal conductivity by means of finite difference method. J. Compos. Mater. 2016;50:795–806. doi: 10.1177/0021998315581511. [DOI] [Google Scholar]

- 53.EN 326-1:1994: Wood-Based Panels-Sampling, Cutting and Inspection—Part 1: Sampling and Cutting of Test Pieces and Expression of Test Results, -Test Method. CEN, European Committee for Standardization; Brussels, Belgium: 1994. [Google Scholar]

- 54.ISO16999, Wood-Based Panels—Sampling and Cutting of Test Pieces. International Organization for Standardization; Geneva, Switzerland: 2003. [Google Scholar]

- 55.EN 322:2005 Wood-Based Panels-Determination of Moisture Content, -Test Method. CEN, European Committee for Standardization; Brussels, Belgium: 2005. [Google Scholar]

- 56.ISO 10534-2:1998: Acoustics-Determination of Sound Absorption Coefficient and Impedance in Impedance Tubes—Part 2: Transfer-Function Method. CEN, European Committee for Standardization; Brussels, Belgium: 1998. ISO/TC 43/SC2 Building Acoustics. [Google Scholar]

- 57.Stegmaier K. Akustikbüro Krämer&Stegmaier, Ingenieurbüro für Schallschutz und Technische Akustik. [(accessed on 14 April 2018)];2018 Available online: http://www.akustik-berlin.de/

- 58.Dettendorfer A. Bachelor’s Thesis. Salzburg University of Applied Sciences; Kuchl, Austria: 2016. Hetta. Ein Ressourcenschonendes Möbel für IKEA. [Google Scholar]

- 59.Niresh J.A., Neelakrishnan S., Subharani S., Kannaian T., Prabhakaran R. Review of acoustic characteristics of materials using impedance tube. ARPN J. Eng. Appl. Sci. 2015;10:3319–3326. [Google Scholar]

- 60.Kundt A. Acoustic Experiments. Philos. Mag. J. Sci. 2009;35:41–48. doi: 10.1080/14786446808639937. [DOI] [Google Scholar]

- 61.Shahani F., Soltani P., Zarrebini M. The analysis of acoustical characteristics and sound absorption coefficient of woven fabrics. Text. Res. J. 2012;82:875–882. doi: 10.1177/0040517511402121. [DOI] [Google Scholar]

- 62.Na Y., Agnhage T., Cho G. Sound Absorption of Multiple Layers of Nanofiber Webs and the Comparison of Measuring Methods for Sound Absorption Coefficients. Fibers Polym. 2012;13:1348–1352. doi: 10.1007/s12221-012-1348-5. [DOI] [Google Scholar]

- 63.Karlinasari L., Hermawan D., Maddu A., Martiandi B., Hadi Y.S. Development of particleboard for acoustical panel from tropical fast growing species. J. Trop. For. Sci. 2012;24:64–69. [Google Scholar]

- 64.Yang H.S., Kim D.J., Kim H.J. Rice straw-wood particle composite for sound absorbing wooden construction materials. Bioresour. Technol. 2003;86:117–121. doi: 10.1016/S0960-8524(02)00163-3. [DOI] [PubMed] [Google Scholar]

- 65.Zulkifli R., Mohd Nor M.J., Mat Tahir M.F., Ismail A.R., Nuawi M.Z. Acoustic properties of multi-layer coir fibers sound absorption panel. J. Appl. Sci. 2008;8:3709–3714. doi: 10.3923/jas.2008.3709.3714. [DOI] [Google Scholar]

- 66.Zulkifli R., Nor M.J.M. Noise control using coconut coir fiber sound absorber with porous layer backing and perforated panel. Am. J. Appl. Sci. 2010;7:260–264. doi: 10.3844/ajassp.2010.260.264. [DOI] [Google Scholar]

- 67.Smardzewski J., Batko W., Kamisinski T., Flach A., Pilch A., Dziurka D., Mirski R., Roszyk E., Majewski A. Experimental study of wood acoustic absorption characteristics. Holzforschung. 2013;68:160. doi: 10.1515/hf-2013-0160. [DOI] [Google Scholar]

- 68.Wassilieff C. Sound absorption of wood-based materials. Appl. Acoust. 1996;48:339–356. doi: 10.1016/0003-682X(96)00013-8. [DOI] [Google Scholar]

- 69.Ghofrani M., Ashori A., Mehrabi R. Mechanical and acoustical properties of particleboards made with date palm branches and vermiculite. Polym. Test. 2017;60:153–159. doi: 10.1016/j.polymertesting.2017.03.028. [DOI] [Google Scholar]

- 70.Gergel T., Danihelova A., Danihelova Z. Acoustic comfort in wooden buildings made from cross laminated timber. Akustika. 2016;25:29–37. [Google Scholar]

- 71.Ilgun A., Cogurcu M.T., Ozdemir C., Kalipci E., Sahinkaya S. Determination of sound transfer coefficient of boron added waste cellulosic and paper mixture panels. Sci. Res. Essay. 2010;5:1530–1535. [Google Scholar]