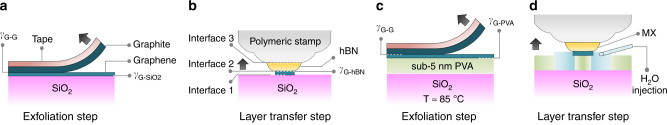

Fig. 1. Fabrication of vdW heterostructures.

Schematic representations of a exfoliation and b layer transfer processing steps in the conventional fabrication methods. In those methods, γG-SiO2 must exceed γG-G during exfoliation. Moreover, γG-hBN must exceed γG-SiO2 during layer transfer. γ denotes the adhesion energy at the interface between two respective materials in contact with each other. These requirements are conflicting, thus complicating the process of heterostructure fabrication. We introduce a simple interface engineering method to overcome this dilemma by using a nanoscale PVA release layer. c In our process, PVA can be tuned to promote exfoliation. d Moreover, selective removal of PVA enables a high-yield layer transfer of the exfoliated flakes without requiring a specialized stamp, hence relaxing the choice of the stamp material (i.e., MX). The black arrows indicate the direction of the applied displacement force during the exfoliation and layer transfer steps.