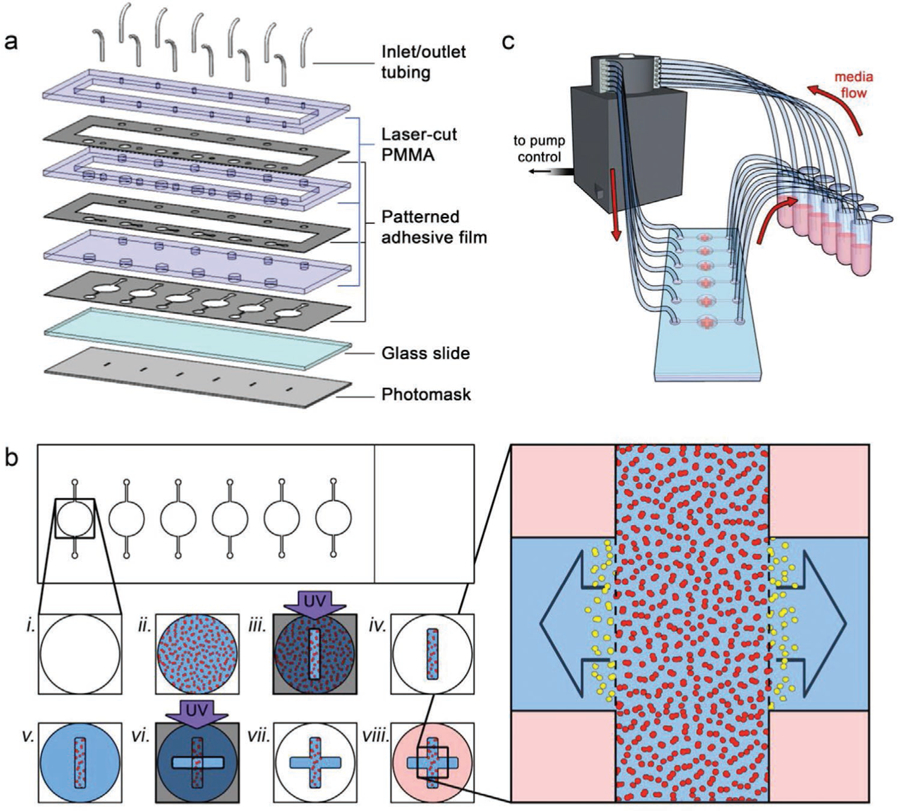

Figure 1.

Device and construct fabrication. a) Exploded view of the components used to form the microfluidic system. See Section 4 for details. b) Process workflow for in situ biofabrication of monolithic, multi-region 3D cell culture constructs. A microfluidic chamber (i) is filled with cells (red) in a photopolymerizable HA hydrogel precursor (ii). Ultraviolet light exposure through a slot photomask is used to cross-link the precursor (iii) and the channel is flushed with clean buffer to leave a cell-laden oblong cuboid (iv). New photopolymerizable HA hydrogel precursor (no cells) is then added to the same chamber (v) and an additional UV exposure is performed through a second slot photomask, perpendicular to the first (vi), adding contiguous cell-free regions to the construct that remain after flushing with clean buffer (vii). Media is added to the final construct (viii) to support embedded cells. Right: expanded view of the construct; the inter-region border (dashed lines) defined by the construct geometry can be used to quantify distance and speed of invading cells (yellow) moving into the cell-free regions. c) Schematic view of experimental setup, showing flow from independent media reservoirs controlled via peristaltic pump.