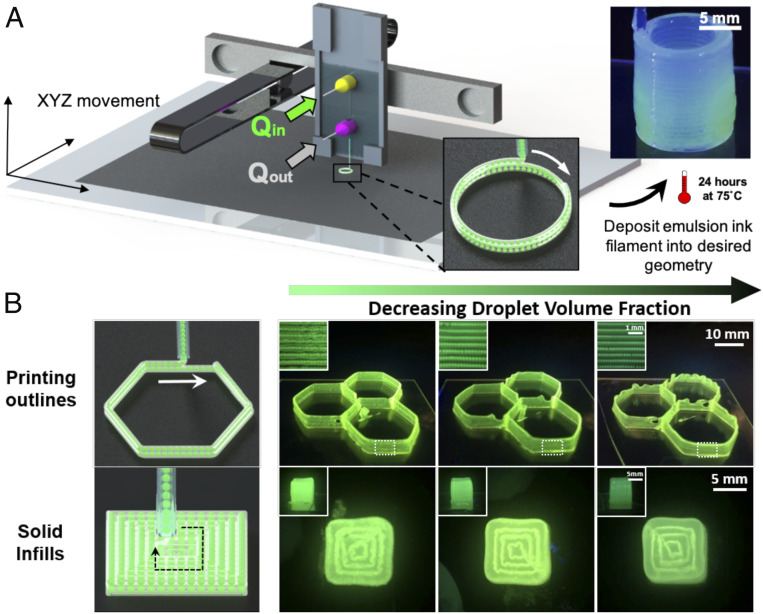

Fig. 1.

In situ dispersion and 3D printing of aqueous droplets in PDMS. (A) Schematic of droplet microfluidic 3D printing process. Qin and Qout refer to the flow rates of the inner (aqueous glycerol) and the outer (PDMS) phase, respectively. Inset shows experimental image of a cylinder printed from PDMS with aqueous droplet (with 62 wt% glycerol) inclusions. The green glow arises from the dissolved sodium fluorescein in the aqueous inner phase. (B) Printing constructs consisting of outlines and solid infills with different droplet volume fractions, which are controlled by adjusting the ratio of Qin and Qout. Droplet volume fractions from Left to Right are 16.7, 9.1, and 4.8%, respectively. Top Insets and Bottom Insets are micrographs of the printed outline objects and front view images of the solid infill objects, respectively.