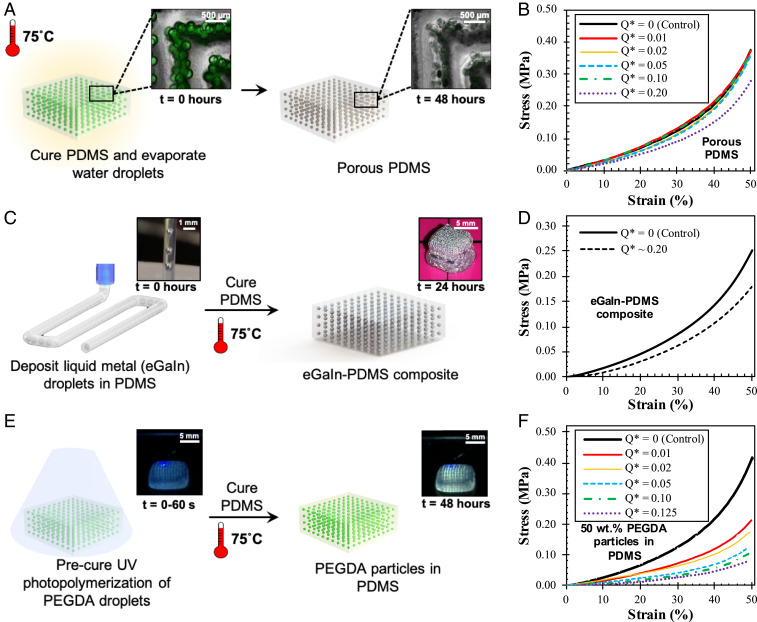

Fig. 3.

Softening in 3D-printed PDMS constructs with different inner phase constituents. (A) Schematic of generating porous PDMS from 3D-printed PDMS with water (no glycerol) droplet inclusions. Insets are micrographs of PDMS prints containing water droplets before and after evaporation of droplets. (B) Representative compressive stress–strain curves of porous PDMS with different Q*. Controls (i.e., Q* = 0) consist of pure PDMS prints with no inner phase present. (C) Schematic of 3D printing liquid metal (eGaIn)-PDMS composites. Left and Right Insets show the dispersal of eGaIn into droplets in PDMS and a 5-mm cube of printed eGaIn-PDMS composites, respectively. (D) Representative compressive stress–strain curves of pure PDMS (control) and eGaIn-PDMS composites. (E) Schematic of converting PEGDA droplets in 3D-printed PDMS into PEGDA particle inclusions via UV photopolymerization. (F) Representative compressive stress–strain curves of PEGDA particles-in-PDMS prints with different Q*.