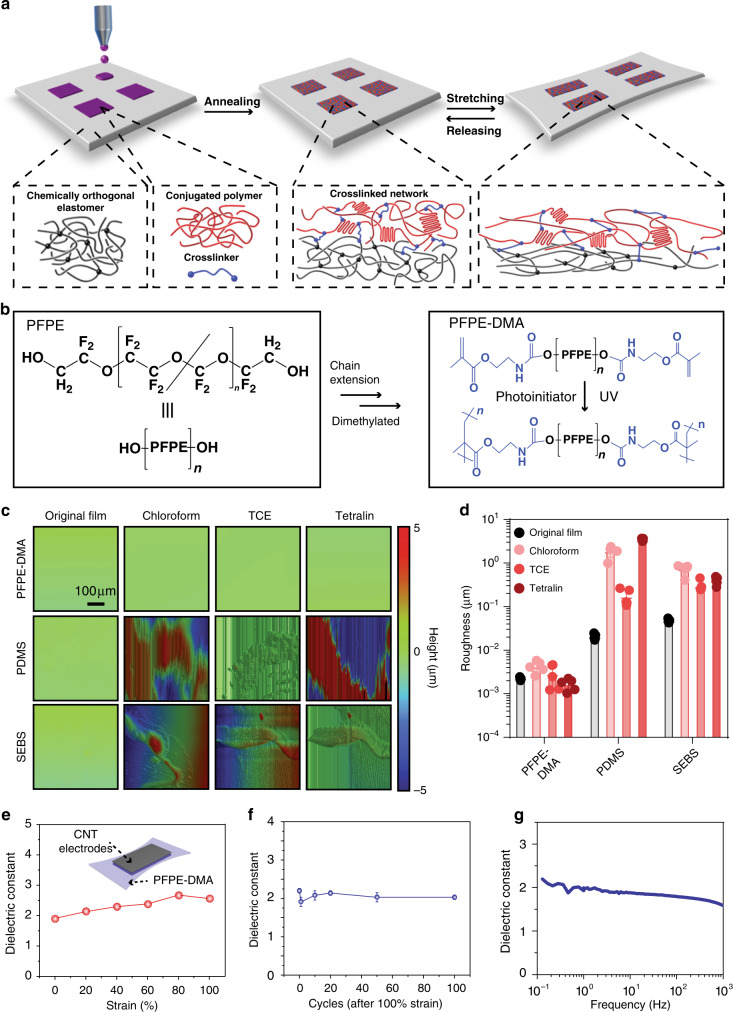

Fig. 1. Perfluorinated elastomeric gate dielectric layers.

a Schematics show the materials design for patterning of stretchable transistors on elastomeric dielectrics by inkjet printing. From left to right: First, semiconducting conjugated polymer with crosslinkers are printed on an ultra-thin elastomer film, which is resistive to that solvents used for semiconducting polymers. Second, crosslinkers crosslink the conjugated semiconducting polymers under thermal anealing, enabling their stretchability. The crosslinkers, at the same time, crosslink conjugated polymers with elastomeric dielectric layer, allowing for a tight bonding between semiconducting and dielectric layers under stretching. b Schematic of molecular structures illustrating the synthesis and photo-crosslinking of dimethacrylate-modified perfluoropolyether (PFPE-DMA) elastomer. c Representative 2D profilometer scanning images showing the roughness of PFPE-DMA and conventional stretchable dielectric thin films (5-µm thick) prior and post to the 1-min treatment of organic solvents, which are used for the solution-processed fabrication of stretchable organic thin-film transistors (OTFTs). TCE: 1,1,2-trichloroethene. Polydimethylsiloxane (PDMS) is standard Sylgard 184 crosslinked PDMS with 10:1 weight ratio of PDMS and crosslinker. The polystyrene-block-poly(ethylene-ran-butylene)-block-polystyrene (SEBS) compounds H1221, with poly(ethylene-co-butylene) volume fractions of 88% was provided by the Asahi Kasei company without crosslinking. d Statistical analysis of surface roughness changes of stretchable dielectric thin films after the solvent treatment (n = 5). e The dielectric constant characterization of PFPE-DMA thin film subjected to uniaxial strains. Inset illustrates the geometry of the freestanding device containing spray-coated carbon nanotube (CNT) stretchable electrodes that sandwich PFPE-DMA film for the dielectric characterization. f Cyclic stability of the dielectric performance of the PFPE-DMA thin film subjected to 100% strain. Values are mean ± S.D. g Dielectric performance of thin-film PFPE-DMA at frequency ranging from 0.1 to 103 Hz.