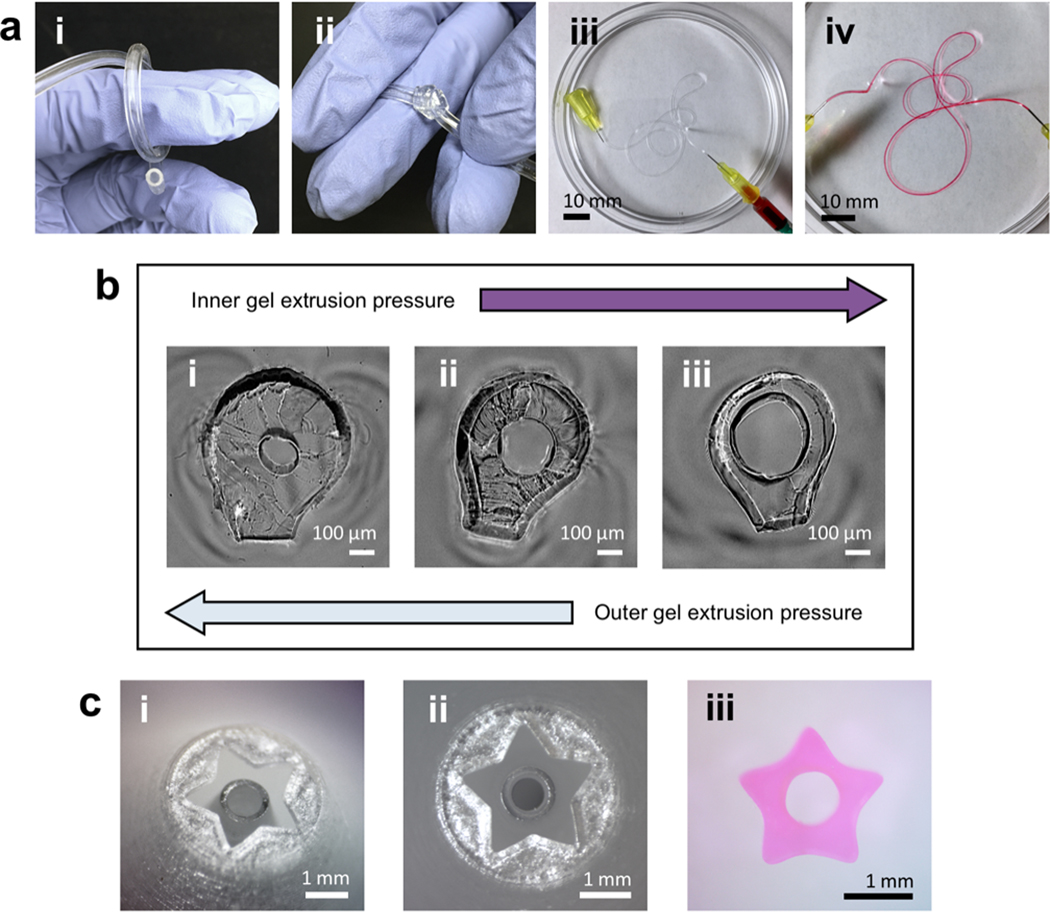

Figure 2.

Tube geometry can be tuned by altering nozzle size and shape as well as extrusion conditions. (a; i, ii) Tubes produced using largest-size (2 mm outer conduit diameter) coaxial nozzle. Tubes have good elasticity and toughness. (a; iii, iv) Tubes fabricated using smallest-size (0.5 mm outer conduit diameter) nozzle. Dye perfusion shows lumen patency. Tube walls were stained as dye began to diffuse through walls. (b) Summary of extrusion-pressure effects on cross-sectional geometry of small tubes. Luminal diameters or wall thicknesses as small as ~150 μm were achieved. (c; i, ii) 5-point star geometry on customized nozzle. (c; iii) Cross-sectional geometry of 5-point star tube produced using star nozzle.