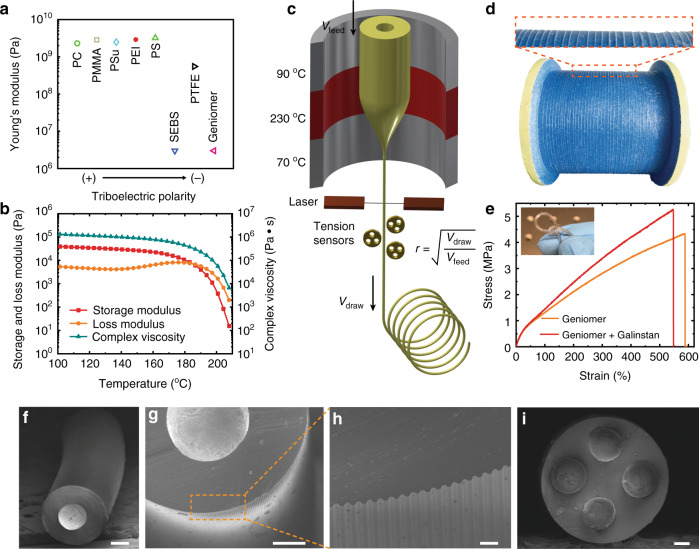

Fig. 1. Materials characterization and fiber fabrication.

a Comparison of Young’s modulus and relative triboelectric polarity of electrical insulating polymers that are compatible with the thermal drawing process. PTFE is also listed for a better comparison. b Rheological properties of Geniomer: storage modulus (G’), loss modulus (G”), and complex viscosity. c Schematic showing thermal drawing process for the production of long fibers. d A roll of 40 m of continuous fiber obtained from a single draw, demonstrating the scalability of drawing process. e Stress–strain curves of a fiber without and with an embedded liquid metal electrode. The inset shows a fiber being randomly knotted. f SEM image of a fiber with a single liquid metal electrode. Scale bar: 200 μm. g, h SEM image of a fiber with microtextured surface. Scale bar: 200 μm (g) and 20 μm (h). i SEM image showing a fiber with four liquid metal electrodes. Scale bar: 200 μm. Note the abbreviations of the polymers in a: PC polycarbonate, PMMA poly(methyl methacrylate), PSu polysulfone, PEI polyetherimide, PS polystyrene, SEBS poly(styrene-b-(ethylene-co-butylene)-b-styrene), PTFE polytetrafluoroethene.